A far more effective approach to cost-cutting is improving productivity, says Hull, and it’s something a good supplier like Guhring can help a shop achieve. It usually requires small investments on the part of the customer, but in the end, is worth it, he adds, and it means reflecting more deeply on how you’re running your shop and machinery.

“Are you saving both time and tool cost? Are you combining multiple operations into one? Are you reducing your tool cost, not simply because the price goes down, but because the tool lasts longer? If you can check all of those boxes, that’s obviously going to be the best solution for you,” he says.

Helping Customers at the Spindle

A good first step in improving productivity is reducing your machining hours, Hull says.

“Machine time is by far the most expensive resource in a shop, so we are always trying to help our customers improve their productivity,” Hull says.

“If you can make your tool last just as long as the previous tool, but you can cut the cycle time in half, you’re going to save way more money than just adding tool life or just reducing the price of the tool,” he says.

Read more: When to Upgrade Your Taps

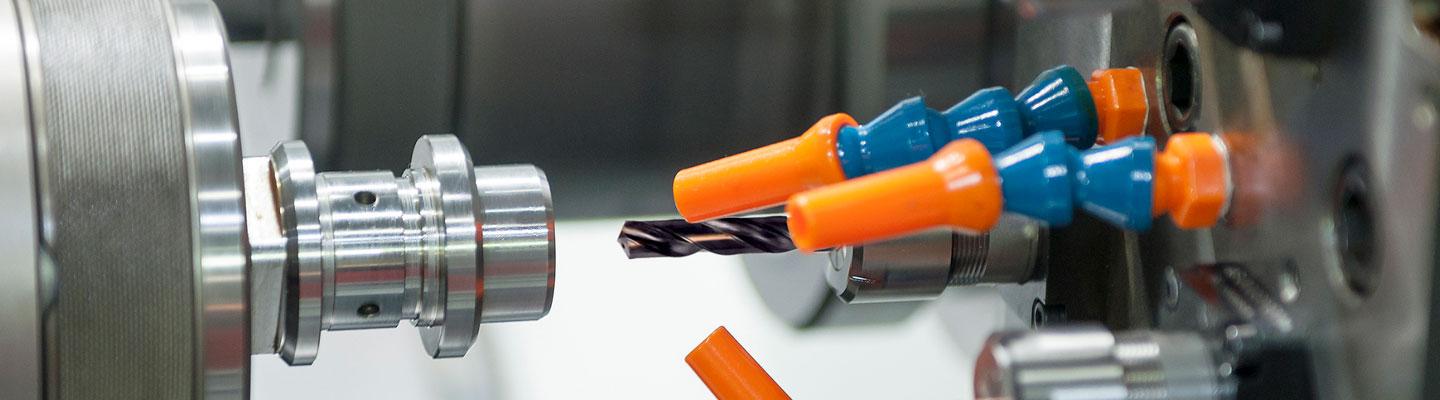

Guhring experts routinely visit customers to help them achieve production cost savings, Hull says. From a round tool focused standpoint, the company has one of the largest sales teams in the United States, and so the ability to get into the shop and help the customer at the spindle is a big benefit, he says, adding that the companies that thrive in difficult times are the ones that can help their customers be more productive.

“Our field sales team is at the customer’s disposal,” he says. “They go into facilities and meet with our customers on a regular basis to assist with potential projects where they can lend their expertise, whether it’s setting up a new job or improving an existing job to ensure the customer is using the best tool for a particular application. And when cutting tool companies partner up with distributors like MSC, who share the same solutions-based approach, the benefits realized by the customer are maximized.”

The sales reps are typically asking questions about the types of materials the customer is machining and assessing the current tool and machine capabilities, Hull says. For example with holemaking applications, the rep may ask how many holes the customer is drilling in each part, or if the customer has coolant through the spindle capability. All this information helps them to narrow down the right tool for the customer’s application.

“You’re never going to be able to get the same type of knowledge from a website or a catalog that you can get from a human being who has actually run all these different tools and all of these different scenarios,” Hull says. “There are so many variables that can affect the operation of a tool that you really do need the input of a human to be fully effective.”

Of course, given the challenge of the COVID-19 pandemic, Guhring’s sales teams are not currently able to enter many customer facilities and shop floors due to visitor restrictions, he says.

“We are having to find alternative ways to help them, so we are using applications like FaceTime where the customer can show the worn tool, send an image of the part or show the rep what’s going on with their machining operation,” he says.

“Those are some of the challenges we face right now. You just have to be creative to find a way to continue to help that customer even though you can’t be on the machine on their shop floor with them at the time.”

Helping with the Skills Gap

Working more closely with your supplier can help your company cope with the widening worker shortage in the manufacturing industry, Hull says.

“In today’s world of machining, experienced skilled tradesmen are one of the most challenging assets for companies to find and keep,” he says. “Everything is so automated, there are a lot of people who know how to operate a machine, but they may not have the experience which allows them to effectively troubleshoot an application. They may know how to set up the part, but when things start going wrong, or they are tasked with improving an application, they may not always know the best place to start or how to identify a problem in order to come up with a solution, so they rely on the technical expertise from the cutting tool manufacturers to assist them.”

Read more: Meet Guhring’s RT100XF: A High-Performance Carbide Drill Developed for Tough Metals

For example, Hull says he recently spoke with a salesperson who was assisting a customer with a titanium drilling job. The customer was trying to drill titanium and was only able to achieve seven to 10 holes per drill. Immediately, they were able to deduce the customer’s drill was not the best one for the job, he says. The customer started out with a cobalt drill and switched to a carbide drill with design features that were more conducive to the application. The customer was ecstatic with the result, Hull says: He got significantly more holes than he was used to getting.

“The customer spent more money on the new tool,” Hull says. “But because of the extra tool life and improved productivity, it’s less expensive to run that pricier carbide drill than it is to run the lower-priced cobalt drill.”

Similarly, Guhring is able to help its customers improve the performance and service life of their cutting tools through simple tool modifications, such as adding coatings, Hull notes.