One Tooling Change Nets Automotive Manufacturer Big Returns

How do you increase productivity and reduce consumable tooling costs without changing anything about the cutting tool itself? That is the story of Wescast Industries Inc., the world’s largest manufacturer of cast exhaust manifolds and turbocharger housings for passenger cars and light trucks.

As a Tier 1 supplier to the automotive market, Wescast Industries specializes in the casting of complex high-temperature components for the passenger cars and light duty trucks. As a global leader in metallurgical development, Wescast Industries harnesses the knowledge and experience of its highly experienced team to deliver innovative solutions to their customers. They design and manufacture components including exhaust manifolds, turbo charger housings, integrated turbo manifolds and other specialized powertrain parts. Their commitment to employee engagement and innovation promotes an environment where continuous improvement is the daily norm.

When the concept of process improvement via toolholding upgrades came to Bob Phillips, Manufacturing Technician at Wescast’s Macomb Township location, he was happy to investigate a possible alternative. Bob noted, “I was looking for a way to get our machines running truer.” It did not take long for him to implement a comprehensive, long-term testing platform from which Wescast would be able to evaluate the claims of one specific vendor.

The Proposal

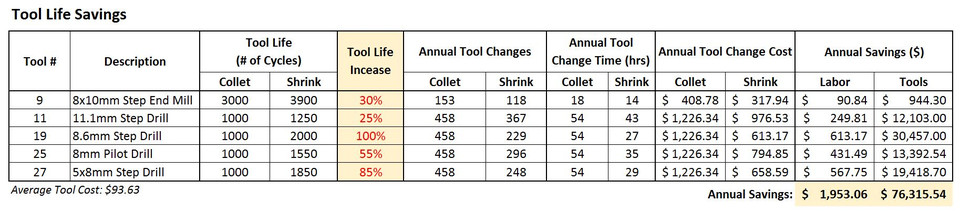

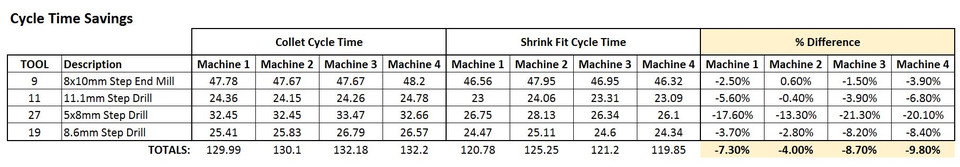

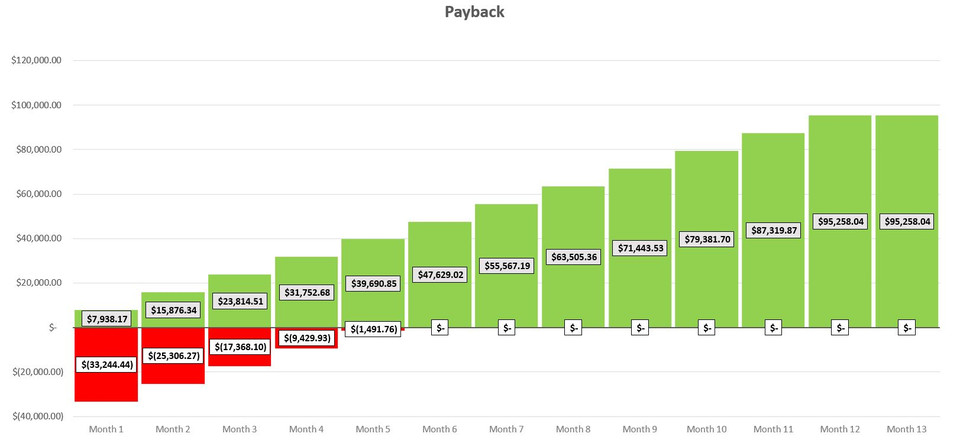

The vendor was HAIMER, a global manufacturing leader of shrink fit toolholding and machine technology. Mike Martin, Regional Manager for HAIMER USA, presented Bob Phillips with a proposal that would guarantee both increased productivity and tool life versus their current collet chuck holders. More specifically, he proposed reducing cycle time by 5% for all round tools with the guarantee that Wescast would net a minimum increase in tool life of 25% for all tools using his shrink chucks.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *