* Each process offers a host of benefits, depending on the application.

Inverter-based welding power sources throw out these old rules.

The “inverter” part of the name refers to how the unit converts primary power to welding power using ultra-fast power switching devices and microprocessor controls.

The now advanced inverter technology was introduced in the mid-80s, so it is extremely reliable and offers many advantages, including:

- Lightweight portability so the operator can easily move the welder to the worksite. A stick/TIG inverter with a 200-amp output, such as the ESAB Rogue ET 200iP PRO, weighs about 18 pounds. A multiprocess (stick/TIG/MIG/flux cored) inverter with a top output of 240 amps, such as the ESAB Rebel EMP 235ic, weighs 53 pounds.

- Input power flexibility. Some inverters can use 230V input for welding thicker metals and, with the addition of a 120V/15A adapter plug, connect to a standard wall outlet for location flexibility.

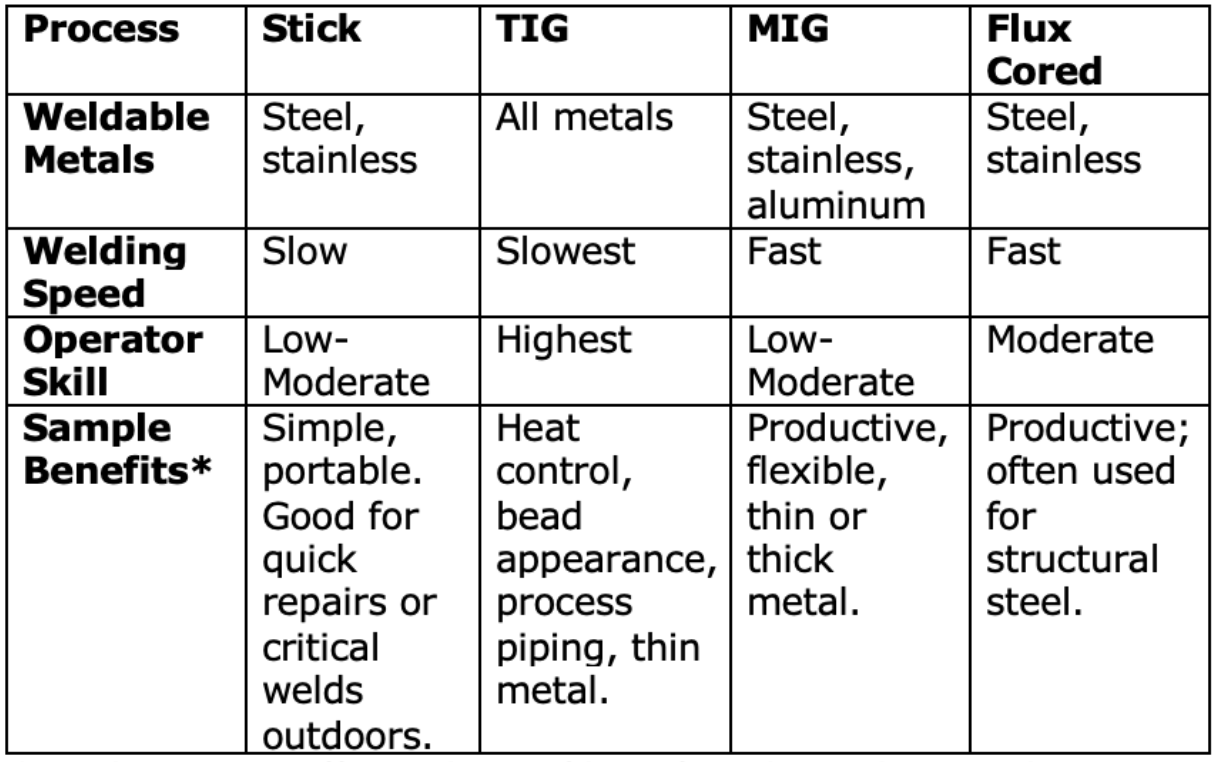

- True all-process welding output with superior arc characteristics. With just a single multiprocess power source, owners can select the best process for the application at hand, or to match the operator’s skill. With microprocessor controls, inverters can sense changing arc conditions and adjust the welding output in milliseconds, improving welding results.

- Advanced user interfaces. Some units offer smartphone-like LCD displays to show operating instructions, the owner’s manual, a parts list and to switch between basic mode to simplify operation or an advanced mode to access a full suite of professional-grade arc controls.

“The next generation of inverters make it easier for anyone to strike an arc, control the arc and end the arc in ways that promote better weld quality and complete jobs faster,” says Dane Windsor, global product manager for light industrial products at ESAB.

As an example, he cites a new function called Smart MIG that simplifies setup and monitors the operator’s technique and continuously adapts to provide a stable arc and superior, repeatable welds.

“You can actually hear Smart MIG fine-tune the arc after a few seconds of welding. It dials in that perfect ‘sizzling bacon’ sound that signifies proper MIG welding parameters,” Windsor says. “This technology reduces downtime when switching between jobs, helps train new operators and can improve consistency between welding stations.”

What Size Welder Should You Buy?

The old rule of thumb is that welding steel requires 1 amp of current for every 0.001 of metal thickness. However, a better method is to select a welder based on two factors:

- The current carrying capacity of the electrode you plan to use. The electrode selected needs to match requirements for welding process, productivity goals, weld bead profile, metallurgy, mechanical properties and acceptable heat input.

- Required duty cycle. Duty cycle is the amount of time a welder may be operated at a given output without exceeding the temperature limits of its components, and it is measured using a 10-minute cycle.

For stick welding, an inverter with a 130-amp output can run a 1/8-inch diameter electrode, while an inverter with a 180-amp output can run a 5/32-inch electrode.

A MIG welder using 120V input has a top output of about 140 amps and is optimized for 0.030-inch wire. The same welder connected to 230V primary may now have a top output of 250 amps and can run 0.035 and 0.045-inch wires for light- and medium-duty fabrication work. For production welding with 0.035 and 0.045-inch wires, look for a unit with a 250-to-300-amp output at 40 percent duty cycle.

Read more: Managing Downtime: A Guide to Improving Shop Productivity During Manufacturing Slowdowns

Plasma or Oxyfuel?

Among metalworkers, debating the use of the plasma cutters and oxygen/acetylene torches gets as heated as Ford vs. Chevy.

The answer is that each process has its place. Plasma cutting takes ordinary shop air and turns it into a concentrated, superheated jet of plasma gas that slices through any metal like a hot knife through butter. Compared to oxyfuel, a manual plasma system:

- Cuts much faster on metals up to about 1 1/2 inches thick.

- Works well on steel, stainless or aluminum (oxyfuel only cuts steel).

- Works great on sheet metal because it minimizes distortion and the heat-affected zone. (Plasma is outstanding for HVAC work and autobody repair).

- Makes it easy to use a template to trace shapes.

- Requires less skill than oxyfuel cutting and doesn’t involve hazardous gases.

- Can also be used for gouging to remove bad welds.

“Today’s leading plasma cutters use inverter technology, so they pack a lot of power per pound,” says Kris Scherm, global manual plasma business & product director at ESAB. “Operators can easily carry them to the job site, then get more work done with faster cutting speeds.”

As an example, Scherm cites the Thermal Dynamics Cutmaster 60i, a unit in the 60-amp category that weighs less than 40 pounds.

Using 230V input power, it can cut and pierce 3/4-inch steel with good cut quality and speed, as well as sever steel up to 1 1/2 inches with a rougher cut surface. The newest plasma cutter in the 40-amp category, the Cutmaster 40, offers 120V/230V primary power flexibility, weighs about 22 pounds and has a rated cut capacity of 1/2 inch. These units also offer multiple handles for easier carrying and LED displays that make setup easier.

While plasma cutting systems are hardened for field use, they still require electricity, so oxyfuel systems offer an advantage when no outlets or generators are available. They also cost less to purchase, can cut much thicker metal (an 8-inch capacity is common) and offer options for an extended reach of several feet (common in scrap yards).

A combination torch outfit, such as the Victor Journeyman, offers attachments for cutting, heating and welding. The heating attachment is especially popular for preheating weldments, which is required by several welding codes. Lastly, premium torches are extremely durable, often being passed down between generations.

“You can increase safety by choosing a torch with built-in check valves and flashback arrestors, or be sure they are available as an option,” says Curt Rocha, global product and business director for gas equipment at ESAB. Check valves prevent gas from flowing back up the hose, and flashback arrestors extinguish a flashback at the torch before it can propagate into the supply line.

Read more: How Do I Avoid Costly Spindle Repairs? Increase Machine Uptime with These Three Steps

Smart Gas Control

Until the last decade, the basic design for gas regulators had changed little in a century. However, seeing the opportunity to improve safety and the user experience, engineers have re-imagined regulator design.

For example, the Victor EDGE 2.0 series features a radically different adjusting knob that incorporates what is known as Shock Limitation and Absorption Mechanism technology. The SLAM mechanism functions like the crumple zone in a car, permitting the knob to absorb the impact in the event of a cylinder fall. The new regulator also incorporates a patented particle trap so the regulator could pass an ASTM G-175 promoted ignition test.

Regulator appearance has changed, too, such as with large diameter delivery gauges that use a high-contrast, color-coded gauge face. Operators can easily see and set delivery pressure from a distance, as well as distinguish it from the cylinder pressure gauge, which is smaller and offset. Even from a distance, operators can tell if they have sufficient cylinder contents and if delivery pressure is within safe and acceptable ranges.

“To evaluate regulator performance, look at a flow data graph,” Rocha says. “A good-performing regulator has a nearly flat line, meaning that it delivers set pressure across the entire range of flow rates. A poor-performing regulator has a curve like an Acapulco cliff diver—it jumps out straight for a short bit, then arcs rapidly down.”

He also notes that a good regulator delivers the set flow rates from extremely heavy flows, such as a large cutting tip or multiflame heating attachment, to extremely small flows, such as a #0 welding tip, which requires just 3 to 5 psig, or pounds per square inch gauge, of oxygen.

Talk to Us!

I've been trying for over a month to email A/P and haven't received ANY response/update back - I've emailed your company website and still no response back, can this be escalated to someone who can respond to my inquiries and give me payment update? It would be greatly appreciated.

Thanks Angela LoPriore

24Hi Angela, I'm sorry to hear this. I will step in and do what I can to help.

26Hi, I’m Jackie with Giant Printing, a small, family-owned fabric printing company in Austin. We produce a unique Backdrop that attaches to the standard pipe & drape provided at most trade shows with our supplied clips. Our Backdrops can be brought to the show in your carry-on bag.

We do all our own printing in-house, using only made in America fabric and inks. By printing in-house, we can meet almost any deadline. Our company goal is to print the very best graphics using the very best fabric which results in a great first impression for you at your trade shows.

Could you please provide me with the name or email of the person that I should contact for your trade show needs? If not, could you please forward my information to them?

Thx!

Jackie

tradeshows@giantprinting.com

Giantprinting.com

go-greenbanners.com

14Leave a reply

Your email address will not be published. Required fields are marked *