Westminster Tool in Plainfield, Connecticut is a family-run business founded by Ray Coombs in 1997 in his basement. In 2003, the company made the move to a brand new, state-of-the-art facility that allowed them to grow and showcase their skills. They expanded their offering from injection-mold systems to composite tooling and high-performance component production for the aerospace industry.

As the skilled labor gap grew, Westminster Tool realized that in order to sustain their business for the long run, they needed a way to reach the new generation of machinists. For five years, the company decided to pause their capital investments and increase their human capital investments. During this time, Westminster Academy was born, an internal onboarding and cross-training platform that each employee uses to develop and track their skills, regardless of their department. This way the whole workforce has a documented way to train more consistently on Westminster Tool’s processes so that they can serve their customers better.

Once Westminster Academy was fully in place, Westminster Tool decided to invest 10% of its revenue back into equipment, primarily in hard milling and high-speed CNC machining. When they committed to the purchase, they started to realize that they needed tool holders that could support their new equipment. Before 2020, Westminster Tool relied heavily on collets and side-locking holders, which have to be trammed in. This process would always take very long to switch out tools but was also inconsistent, since each user could set up the tools differently. It was especially hard to train employees on this tool holder system because of how much effort it takes to set up the tool in collets.

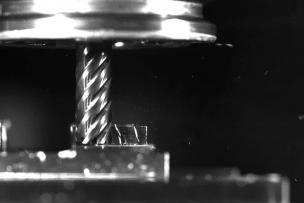

When they started to look for solutions, HAIMER was recommended. Colby Coombs, Chief Financial Officer and son of Ray Coombs, started doing some research and connected with Mike O’Connor, Regional Sales Manager for Haimer USA who introduced him to shrink fit technology. After hearing about the benefits from Mike and seeing the technology in action, Westminster Tool decided to invest in the HAIMER Power Clamp Special Edition and HAIMER Standard Shrink Fit tool holders.

Soon after Mike trained the Westminster Tool team on the new equipment, they started to see the benefits firsthand. “We have seen close to a 40% increase in tool life now after switching to HAIMER products,” Colby says. “We are easing away from collet-style tool holders every single time and we are replacing them with HAIMER.”

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *