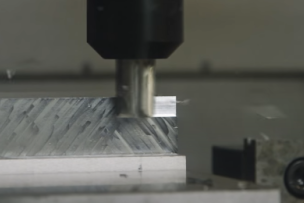

When machine shops buy milling tools, they have two primary considerations: tool life and productivity. Those parameters, unfortunately, have what engineers refer to as a negative connection.

Which is a technical way of saying that when one increases, the other decreases.

“You generally can’t get both because the harder you feed a tool, the more it’s going to wear,” says Daniel Dominski, an applications engineer at OSG, a leading supplier of end mills and other cutting tools to industries from aerospace to automotive and heavy manufacturing.

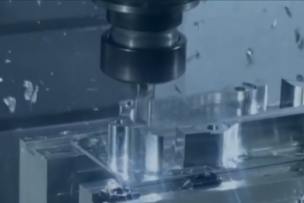

It’s a conundrum OSG addressed with its A Brand AE-N end mills, three-fluted instruments with a diamond-like carbon coating that gives heightened smoothness and wear-resistance and a larger-diameter core that enables higher operating speeds without overtaxing the tool and shortening its life span.

Longer Tool Life Yields Big Savings

That’s a win-win for machine shop budgets: Not only are they saving on tool costs, which typically amount to less than 5 percent of the production expenses, they’re also saving on labor and machinery, which together account for more than half.

While the tools have a higher price tag than conventional bright-coated alternatives, “the increase in tool life from our DLC coatings can result in great cost savings,” Dominski says.

To show clients how, OSG visits worksites in person and compiles cost-savings documentation. Overall, the result for machine shop customers is somewhat like the consumer experience of paying more for a high-quality winter coat that lasts for 10 years rather than picking up a discount version that may survive just one season.

“You get a tool with exceptional tool life,” he says. “You might require fewer tool changes and you’re getting better productivity from this tool because it runs at faster speeds.”

The A Brand series represents an upgrade from OSG’s older Blizzard mills that offered diamond-like carbon, or DLC, coatings only as modifications, adding a couple of weeks to delivery time.

The AE-N mills “provide a more premium solution right off the shelf, with no waiting for modifications,” Dominski says.

Rapidly Expanding Market

The speedier delivery further hones OSG’s competitive edge in the lucrative cutting tools market, which is expected to grow an average of 3.96 percent a year through 2025, an expansion of about $4.26 billion, according to global technology research and advisory company Technavio.That’s roughly a third of the $12.6 billion growth that Technavio forecasts in the metal machining market overall, with rising demand from the oil, gas and automotive industries.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *