With a wealth of abrasives options available, there’s no reason to settle for anything less than the best one for the job. Here are three new products you need to know about: Norton’s RazorStar, 3M’s Cubitron 3 and Osborn’s Honey Badger.

Leaf through any abrasives catalog or surf any supplier’s website and you’ll quickly discover an important fact: There’s no shortage of choices.

And the multitude of options—from grain size, shape and hardness to the bonding material that holds everything together—can make it tough to find the most productive, cost-effective abrasive for the job.

Still, there’s simply no reason to settle for anything but the best performance. Abrasives manufacturers offer plenty of application and safety advice in the form of videos and written content. They also provide technical support via email, chat and phone, not to mention customer training classes.

That’s good news for shops trying to optimize their grinding operations, whether they’re using wheels, discs, pads, belts, brushes or all of the above.

But let’s assume you’ve availed yourself of these resources. Your abrasives remove metal quickly and cleanly. There’s no buildup, burning or chatter, and ground surfaces come out clean and smooth. Give yourself a pat on the back. Your grinding department is running like the proverbial well-oiled machine. Now what?

Sadly, there’s no sitting on one’s laurels in today’s competitive manufacturing environment, content with the performance of legacy products and processes. As W. Edwards Deming stated more than four decades ago in his must-have book Out of the Crisis: “Improvement of quality and productivity, to be successful in any company, must be a learning process.”

The well-known lecturer and business consultant also said improvement is not compulsory, but voluntary, which is why metalworkers must remain both enthusiastic and diligent in their never-ending quest for better tools and techniques.

To that end, here are several new and very notable product offerings from three of the industry’s leading abrasive suppliers, all of which can help shops become more efficient and profitable.

Norton RazorStar

It’s possible that you tried fiber discs years ago for weld prep and cleanup and found them less productive than the aluminum oxide wheels you were using.

While that viewpoint may have changed with the development of zirconia-alumina, which made fiber discs more productive but still required significant force to keep abrasive grains sharp, the subsequent introduction of ceramic grains was revolutionary.

Suddenly, workers discovered they could reduce grind times with far less effort and enjoy longer disc life to boot. The trend continued as manufacturers like Norton | St. Gobain Abrasives developed ever more advanced ceramics and topcoats, improving grinding performance across the board, even in challenging materials such as aluminum, titanium and heat-resistant superalloys.

Now, Norton has taken ceramic technology one step further with the introduction of its next-generation, engineered-shape abrasive, the RazorStar. Through extensive collaboration with its product development teams and more than 100 design iterations, researchers discovered that a star-shaped grain made of highly pure nanoscale alumina crystals—if made to stand in an upright orientation—would not only be self-sharpening but cut cooler, longer and more predictably than conventional abrasives.

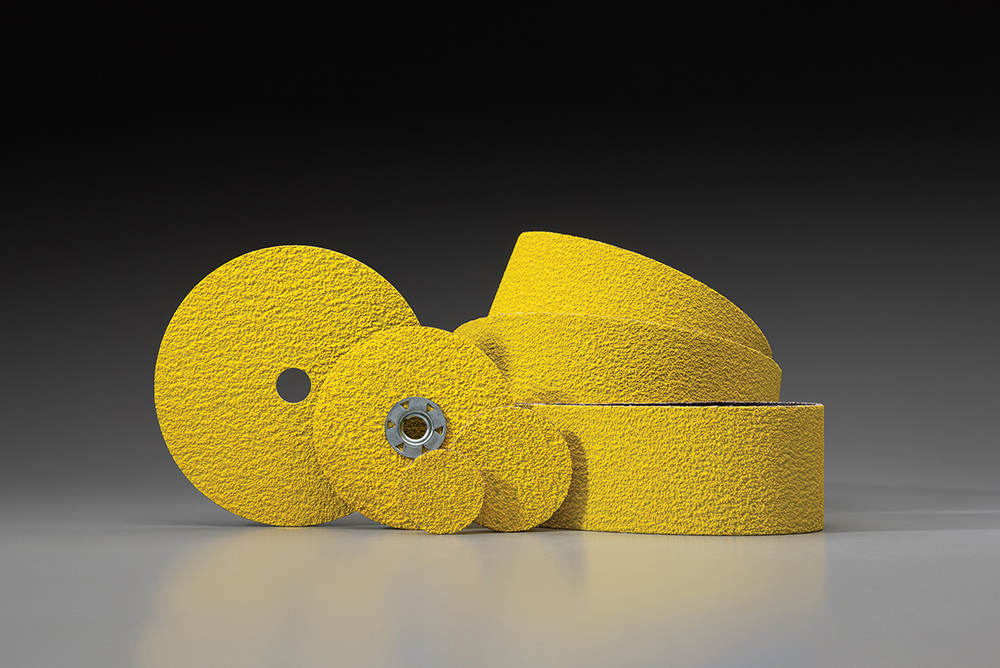

They coupled the patented grain design with an optimized “layered architecture” of backing and resin bonding, resulting in a sharp, coated abrasive that’s available in belts, fiber discs and quick-change discs.

Internal testing has shown that, compared with a standard ceramic disc, the RazorStar removes nearly 100 percent more metal. It’s also said to exhibit less wear while boasting a faster cut rate and lower power consumption across a broad range of alloys and applications.

3M Cubitron 3

Another advance comes from Minnesota, where 3M recently released the newest member of its Cubitron family, the Cubitron 3, which cuts through metal far more quickly and with less heat than conventional abrasive grains. The coated abrasive builds on the microreplication technology used in its Cubitron II products, which debuted in 2009.

Both feature sharp pyramid-shaped peaks that “easily slice” through stainless steel, aluminum and heat-sensitive alloys, but the Cubitron 3 goes a step further with a reengineered grain design and proprietary resin binding for increased life.

For example, Cubitron 3 fiber discs reportedly deliver an initial cut rate up to 53 percent faster and sustained cutting up to 43 percent faster than the Cubitron II, but at the same price point. Depressed center grinding wheels equipped with the reengineered, precision-shaped grain last up to 50 percent longer, making them ideal for robotic grinding cells where downtime is critical.

They also provide better balance and a smoother cutting action, minimizing operator fatigue in manual grinding applications.

And Cubitron 3 cutoff wheels, the company says, last three times longer than their predecessor, with 10 percent faster cutting speeds besides. The latter also ships in resealable bags for maximum shelf life and, as with other 3M products, carries the Sustainable European Abrasive Manufacturers (SEAM) seal to demonstrate the company’s commitment to sustainability.

Osborn Honey Badger

In the brush market, meanwhile, the new Honey Badger, a double-stringer bead brush from Osborn, is designed for aggressive surface cleaning in welding and metal fabrication.

Introduced at the 2022 FABTECH Exhibition, it builds on the success of the company’s well-known 4-Inch TufBrush Stringer Bead Brush. What’s different is that the Honey Badger is like two brushes in one, able to clear slag and debris from both sides of a weld simultaneously.

There's more to the Honey Badger than additional bristles, though.

Osborn has addressed requests from customers looking for a brush with a longer life span and lower operating force that can still get the job done in less time.

The company achieved that goal by equipping the Honey Badger with a special faceplate and nut that supports two sets of wire knots, doubling its life and aggressiveness while reducing the risk of stray wires coming loose during operation.

According to a company spokesperson, “You can use it on anything that you use a wire wheel on now, and it’s just going to work faster, work better and last longer.”

How have upgrades in abrasives improved your shop’s performance? Tell us in the comments below.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *