Seco is one of the world’s largest providers of comprehensive metal cutting solutions for milling, stationary tools, holemaking and tooling systems. For over 80 years, we have been more than just a cutting tool provider. We develop and supply the technologies, processes and supports that manufacturers depend on to maximize productivity and profitability.

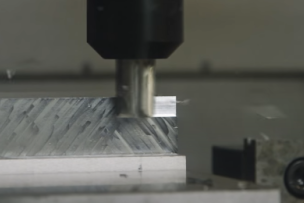

The trend for near-net-shape production and 3D printing is helping to drive demand for extremely small end mills. Far from a niche product, such mills can be found in countless applications.

Imagine an end mill as thin as a light-weight fishing line or the cotton thread you use to repair clothes. What possible uses could it have?

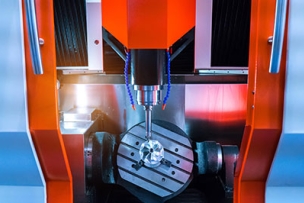

Far more than you might expect, according to Massimo Paletta and Ruud Zanders, two Seco experts in the field of micro machining. Seco’s range of miniature solid carbide end mills and ballnose cutters can be found in just about every industry and are used to produce products we all use every day.

“Our range includes end mills from 3 millimeters in diameter right down to 0.2 millimeters,” explains Massimo, who is an application engineer. “You can find them in use in the mold and die industry, being used to create electrical components, and in dental and medical applications. When you sit in a car, the electrical connectors, the circuit boards and parts in the engine and steering systems have probably been made using miniature end mills. We sell to every market segment.”

.jpg?itok=clvY6OP5)

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *