Material-Specific Tooling – Does it Really Make Much of a Difference?

Achieving better tool life in challenging materials is a target for cutting tool R&D teams, and is at the core of many highly specialized designs.

Achieving better tool life in challenging materials is a target for cutting tool R&D teams, and is at the core of many highly specialized designs.

Cutting tool manufacturers with robust R&D departments are continually striving to optimize a tool’s performance in challenging materials or applications, often with the goal of extending the tool’s productivity and tool life. It comes as no surprise that the material being machined plays an enormous role in the tool’s potential longevity.

The machining characteristics of many materials can be quite detrimental to the life of the cutting tools, resulting in plastic deformation, abrasive wear, material buildup on cutting edges, and poor chip evacuation. To some extent, these effects can be reduced by adjusting the operating parameters and/or coolant, but the reduction in tool life is still an issue with a negative effect on production costs. Achieving better tool life in challenging materials is therefore a target for cutting tool R&D teams, and is at the core of many highly specialized designs.

A cutting tool developed as a material specialist may have at its “roots” a customized carbide substrate. Minute changes in grain size and cobalt content, combined with carefully controlled sintering processes, will produce carbide that has varying degrees of hardness and toughness adapted to tackle a given workpiece material and cutting operation.

Coatings enhance a cutting tool’s features by providing additional heat and abrasion resistance, and even aiding in reducing friction and improving chip flow. The details of coating composition and characteristics could take up an entire book, but the selection of a coating that best addresses a given workpiece material is also essential.

Highly specialized point designs, cutting edge geometries and edge preparations -- such as honing or polishing -- also factor in to a cutting tool’s performance in a challenging material. Is the desired result a sharp, shearing action that cleanly cuts a soft or gummy material? Or is the goal a lower horsepower draw, with reduced axial or radial cutting forces? Are there coolant holes integrated into the tool to deliver coolant right to the cutting edge for lubrication, heat dissipation, and chip evacuation? Manufacturers’ R&D departments fine-tune every element of a tool’s design to take these factors into account.

The design of the flutes and the helix angle of the tool play a very important role where chip formation and evacuation is a priority. A parabolic flute design allows plenty of space to evacuate a nicely curled chip, while maintaining a strong core, resulting in increased stability. Selecting the ideal balance of features like these are key to developing a cutting tool that’s well-suited to deal with challenging materials.

Stainless steels are well-known examples of materials that present machining challenges, with tool life being a common complaint. Drilling operations require ideal chip formation and efficient evacuation in order to succeed in stainless, as well as contending with elevated heat. A drill designed to excel in stainless can have an enormous advantage over a more “universal” design.

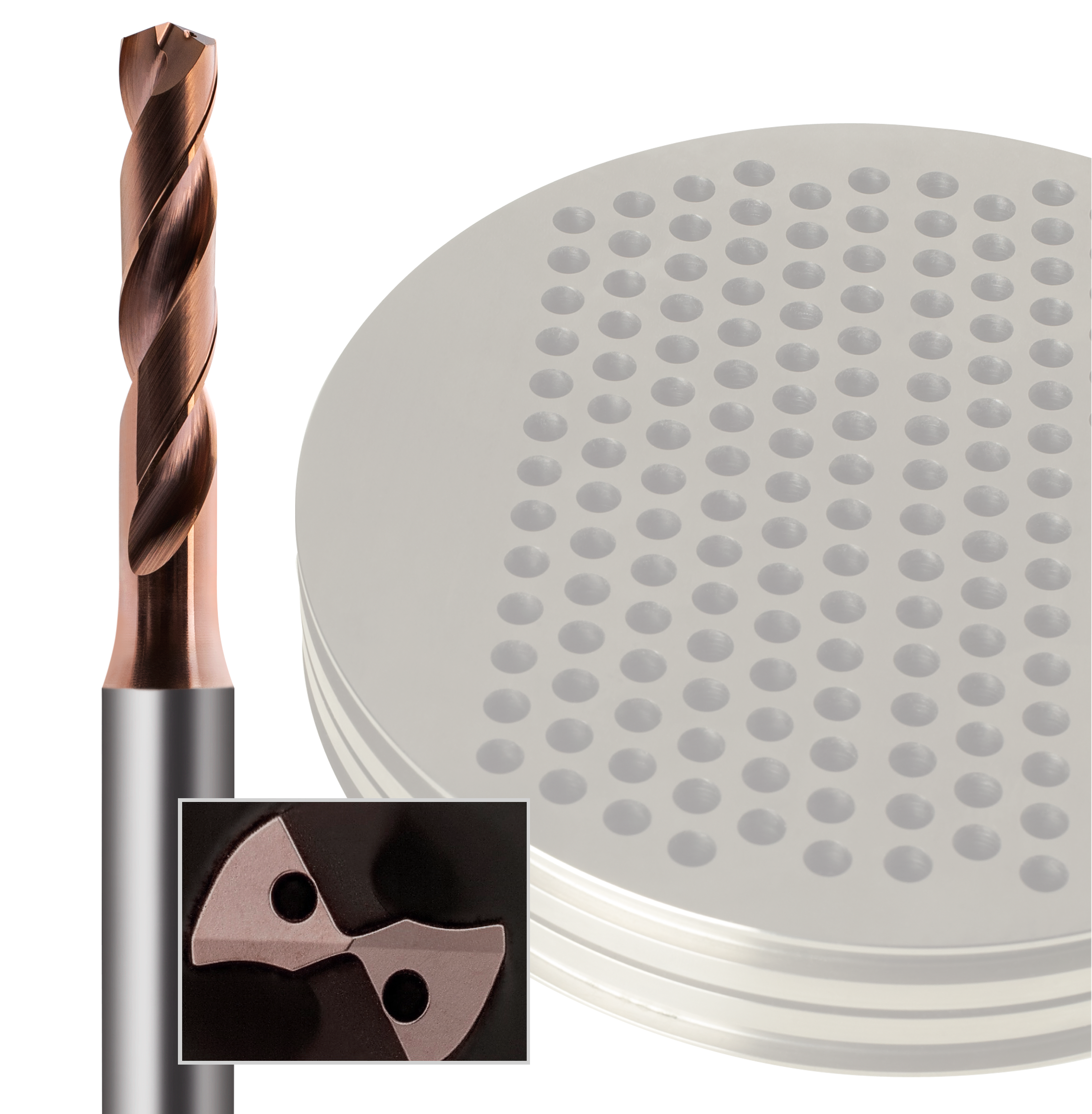

This was definitely the case for a prototype machine shop in the Southeast which specializes in short-to-medium runs in difficult materials. Drilling 300 small holes per part in 316 stainless steel to manufacture heat exchanger plates was giving their carbide micro drill a real challenge. The drill, with coolant through the tool and AlCrN coating, was achieving about 600 holes – or drilling two plates – before needing to be reground.

When they tested a carbide micro drill specifically designed for stainless steels, they were hoping to improve on that tool life and reduce the number of tool changes needed. The specialist – a Guhring ExclusiveLine micro-drill VA – tripled the tool life of the original carbide drill. Running at the same speeds and feeds as the original drill, the stainless steel specialist drilled 2,400 holes and after magnified inspection it was determined that the drill could have kept going.

The Guhring drill is made from a carbide substrate specifically designed for micro-drilling in stainless, with reduced grain size for increased hardness and a higher cobalt content for added toughness. The drill’s geometry has several features to achieve success in long-chipping and tough materials like stainless: A concave, radiused cutting edge results in a consistent drilling process with low cutting forces, and a specialized flute profile helps to produce shorter, more manageable chips. The Perrox coating on the micro VA drill uses HiPIMS coating technology to create a tougher, harder and smoother coating than traditional PVD coatings, and has improved wear resistance. A high-precision honing process on the cutting edge and post-coating process on the drill flutes work together to ensure an optimal cutting action with improve chip evacuation.

With the huge improvement in tool life and reduced downtime to exchange dull drills, this shop saved just over 27% in this drilling operation, which added up to nearly $50 per heat exchanger plate. This is just one great example of the benefits of using a cutting tool designed to tackle a challenging material.

For more than 100 years, Guhring® has provided innovative solutions for round cutting tools. Guhring's extensive line of cutting tools are manufactured on machines and equipment designed and built by Guhring, ensuring the highest level of quality, accuracy and consistency. From micro drills and deep hole drills to cutting taps and finishing end mills, Guhring has the right solution for every job.