Manufacturing and Process Engineer Career Guide: Salaries, Skills and Job Descriptions

Why these roles are in demand and the path to achieving success in these critical positions.

Why these roles are in demand and the path to achieving success in these critical positions.

The evolution of manufacturing work, particularly as job shops grow and evolve, makes the role of the engineer a critical one for success. What’s involved, what’s the career path and what salaries do process and manufacturing engineers command? We take a closer look.

With the evolution of the manufacturing shop floor—Industry 4.0, lean manufacturing, the Industrial Internet of Things and the rise of automation—the need for engineering has gained critical mass.

Today, there are more than 4.48 million manufacturing engineers in the U.S. workforce, and the role has been growing at a rate of 4.23 percent annually, according to the statistical site Data USA. The site notes that the geographic regions with the highest concentration of manufacturing engineering degree recipients are in and around Los Angeles; Menomonie, Wisconsin; and Raleigh, North Carolina.

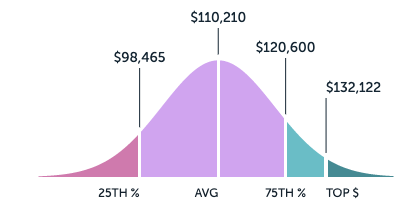

In Los Angeles, the cost of living pushes the salaries for process engineers far above the average of $73,500 nationally:

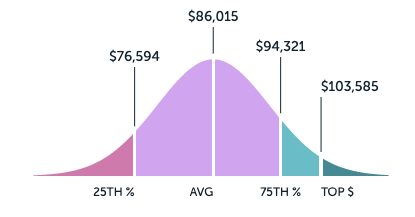

By comparison, the salaries for comparable positions in Menomonie, another hot market for process engineers, are just slightly elevated:

“Industrial engineering is a great field for people who enjoy learning every aspect of how something works and then questioning those processes until they create something better,” explains Career Builder. “This is an ideal career trajectory if you enjoy taking things apart and finding better ways to assemble them again.”

In the most basic sense, engineers are the glue between the products and parts that a business will produce and the machinists and systems that will craft and create them.

You will hear both of these job titles—process and manufacturing engineer—in the manufacturing industry. The process engineer works most notably in the food, pharmaceutical and chemical industries. While the manufacturing engineer tends to work in areas such as aerospace and automobiles.

“The distinction is somewhat blurred by industry’s loose use of the word ‘process,’ ” notes a Career Trend article.

In both cases, these roles have gained prominence because of the need to continually do more with less and drive up revenue across manufacturing facilities in all industry verticals.

The scope of work is quite similar, as the Career Trend definitions show:

The process engineer will “design equipment, install control systems, upgrade the processes, and factor in environmental and health protection.”

The manufacturing engineer is responsible for “designing efficiency, cost-effectiveness, environmental and safety controls into a process.”

In both instances, optimization is a critical part of this work, which points to the chief reason that these jobs are on the rise in manufacturing: How can a business get the most out of its team, tools and process to achieve speed to market and return on investment?

“Process engineering is at work during all stages of a continuous manufacturing process,” explains a post on Get ReSkilled, a blog focused on manufacturing in the pharma and biotech industries. “These engineers can be designing innovative processes and equipment for a new facility or they can be involved in the modification and optimization of equipment and processes that are already in place.”

That’s a driving role of the process or manufacturing engineer. The engineer or engineers will work closely with the machinists, who know how things are made, to design each product and develop the specifications for creating it in the most effective and efficient way.

For the small company or startup, this engineer often might be the owner or a shop supervisor. But as a company grows, the need for a dedicated engineer or even an engineering team typically becomes a reality.

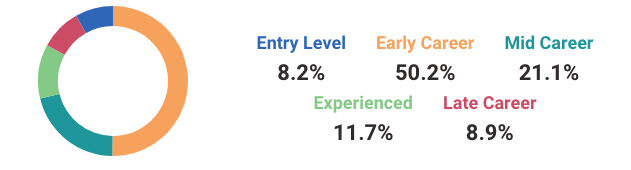

That this role is still emerging can be seen in how manufacturing engineers self-report where they are in their careers. Most still consider themselves to be in the early part of their careers based on a Payscale.com survey of 12,228 manufacturing engineers:

Here’s a quick look at the work tasks, as detailed by Payscale.com, for both process engineers and manufacturing engineers, which have clear overlap.

Lead production operations.

Develop workflow and plan for equipment, procedures and policies to increase efficiency.

Introduce innovations in production and identify cost-saving opportunities.

Provide training to make sure processes and equipment are used effectively.

Manage maintenance and mechanical emergencies.

Make sure employees and equipment comply with safety regulations.

Design shop floor for most efficient and productive layout.

Train team of manufacturing engineers.

Revamp machine design to business’s unique production needs.

Develop and lead teams to address production and product issues.

Define and implement cost savings and safety initiatives.

Understand why TCO matters and the factors at play in driving it down in “How to Lean In on Total Cost of Ownership in MRO.” (Pssst: Engineering is one of the factors.)

For both these job categories the salaries are decent, though process engineers tend to command slightly higher pay as they often have a wider set of responsibilities and may oversee a team of manufacturing engineers.

The salary for process engineers across industries will range between a starting wage of $50,000 and can reach above $102,000, according to Payscale.com.

Here’s a look at what several large manufacturers pay employees in this role:

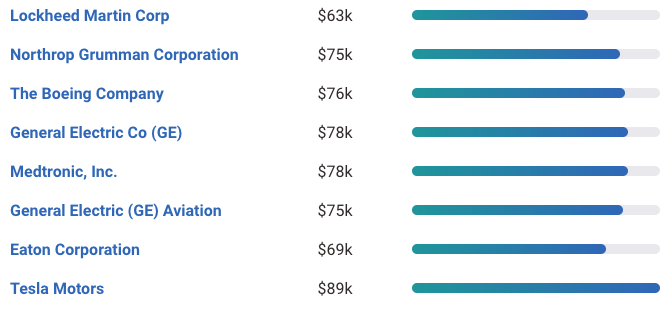

Salaries for manufacturing engineers interestingly start a bit higher than for process engineers but top out about $10,000 lower, with a range between $53,000 and $90,000 typically. The average salary is just shy of $69,000.

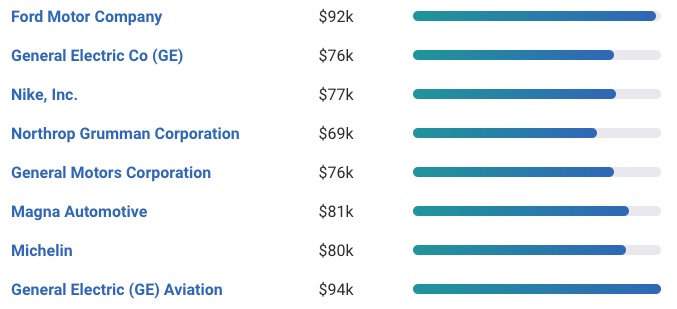

And here is a comparable look at what some large manufacturers are paying their manufacturing engineers:

For both of these jobs, successful applicants typically have at minimum a bachelor’s degree in engineering.

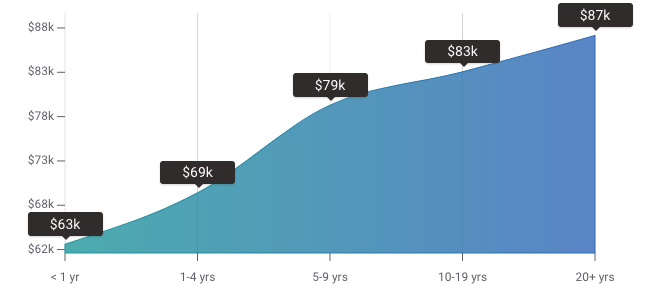

But experience on the job also matters.

“Management experience or business qualifications with accompanying engineering awareness or experience can also provide a route into these positions,” points out the Get Reskilled article.

Payscale.com adds that most process engineers also have “at least eight years of experience in a similar manufacturing engineering position.” It further notes that a certified manufacturing engineer (CMfgE) certification is often preferred too.

That desired on-the-job experience makes a machinist who has also attained an engineering degree particularly marketable. It’s one reason that many businesses will help with educational costs if their machinists choose to go back to school for a higher-education degree.

More experience equates to more pay for the process engineer:

An in-depth knowledge of machining cannot be understated, as one engineer responded in a survey for Engineering.com: “Not many people know their way around a machine shop. [Learning machining] has made me that much better of an engineer.”

MSC has partnered with Tooling U-SME, a leader in manufacturing for nearly 90 years, to offer online training packages that support core manufacturing roles by helping develop and maintain the necessary skills to keep up with new innovations and advanced manufacturing.

Learn More and Start Your FREE Trial Today

Does your shop have a dedicated process or manufacturing engineer? Share how this role has evolved in your business.

“It turns out many young engineers can have strong theoretical backgrounds and yet be stymied when it comes to applying that knowledge to real-world problems.”

Those are the words of Kevin Perry, a veteran in the learning and development field, in an interview with the American Society of Mechanical Engineers.

It points to a chief truth at the heart of the engineering skills gap in manufacturing: Companies want engineers to be able to come in and improve how their businesses design and produce products. Yet often, engineers don’t understand or have basic knowledge of the chief components of products in a particular industry.

Perry pointed to the auto industry as a for instance, where such knowledge “might include a basic understanding of the power train and chassis.”

It’s in part an evolution in how people learn, he explains.

“There was a time when folks took things apart to see how they worked. Some of that was people working on their cars, for example, but a lot came from people growing up on farms who were accustomed to working on agricultural equipment. Today, that’s mostly gone. Young people now grow up in front of screens, and everything is simulated and part of a game.”

Read more about the skills gap on Better MRO here.

![Abrasive Selection Guide: Choosing the Right Grinding and Finishing Solutions [Infographic]](https://images.ctfassets.net/5j4ln2up7bt7/1PP33ignTLl0VM0awoD294/e585b6ab26bf3bf71e34aa622fcf3437/GettyImages-905155112_Image3-thumb.jpg)