Lengthy shutdowns can lead to potentially costly problems in your coolant sump. As the COVID-19 outbreak forces some manufacturers to contemplate extended shutdowns, here are proven steps you can take to protect your equipment when production slows.

Production slowdowns are a normal feature of the manufacturing sector, but the COVID-19 threat means companies in the metalworking industry face the possibility of protracted production shutdowns if demand slows further down the supply chain.

Proper maintenance of metalworking fluid is important during this time. It can help preserve the stability of the coolant in your system and prevent unnecessary delays and costs due to repairs when production returns to normal.

Broadly, there are three areas where metalworking shops should concentrate their efforts: circulation, concentration and frequent testing. Maintaining the circulation of metalworking fluids is vital to minimize bacteria and fungus growth, and frequently checking the concentration levels can help avoid equipment damage, corrosion and rust.

Here’s a breakdown of the three main areas:

No. 1: Keep Your Sump Coolant Fluids Moving

With machining systems typically running water-based fluids that circulate 24/7, maintaining fluid circulation during downtime is vital. Doing so forces oxygen into the system so fluid won’t become stagnant, helping to avoid the growth of bacteria and fungus. Bacteria also tends to flourish in stagnant systems that include a buildup of metalworking chips. Another cause is when a layer of oil collects in the sump, preventing aeration.

Read more: Looking to learn more about why coolant cleaning is so important? Check out these "5 Reasons to Keep Machining Coolant Clean."

Circulating the system as much as possible during a shutdown will prolong the life of the fluid. This can be achieved by periodically running your circulation pumps, says Jim Brumgard, application engineer at Castrol.

“The circulation doesn’t have to be constant,” he says. “For example, you can put the pumps on a timer so that they run 10 minutes out of every hour. If the fluid isn’t moving for 50 minutes out of 60, that’s not a problem.”

Brumgard likens the process to letting cold water trickle through a faucet in your home during cold winter months to prevent water pipes from freezing.

You should also consider removing any floating oil layers from your fluids using mechanical skimmers, he adds. Oil creates a barrier to the liquid’s air supply and promotes bacteria growth, which can increase fluid acidity (the pH will drop) and lead to corrosion elsewhere in your system. Skimmers or shop vacuums help remove this tramp oil layer and help to preserve the coolant, Brumgard says.

If you’re not able to circulate your fluids, you can also empty and clean your machine sumps. In this instance, you can use a water-based rust inhibitor to spray inside your machines. Lines should also be checked for any bacterial contamination.

No. 2: Maintain Your Sump Coolant Solution’s pH Levels

A low pH is the enemy of a coolant sump. Once your pH level declines, your coolant begins to lose its anti-rust capabilities, bacteria grows more quickly, and the emulsion itself can degrade.

This is why it’s important to frequently check your coolant solution concentration. If the concentration of a fluid drops, certain product components may become so low that the fluid no longer protects your machinery.

Most products include a small amount of biocide and fungicide, and continually monitoring the concentration ensures that the product chemistry is maintained. You can use an optical refractometer to do this daily.

Got a machining and tooling related question? Click here to ask our team of experts.

“Overall, you’re fighting on two fronts: contamination and depletion,” Brumgard says. “The built-in chemistry used to prevent bacteria growth and rust will eventually deplete if you neglect maintaining the concentration. When you use water-based fluids, this is always an issue.”

A particular challenge for water-based fluids is evaporation, which tends to happen in greater volumes than you would expect, he notes. As the lost water is replaced, you risk the contaminating effect of a buildup of minerals. The mineral components vary, depending on the source for the makeup water, and they can have a destabilizing effect on emulsions and rust protection components. Water quality is therefore important. Deionized water and RO (reverse osmosis) water are essentially mineral-free and avoid the detrimental effect of high hardness and other elements.

It’s also important to make sure you have additives on hand (fungicide, for example), or at least on order, so they are readily available when you need them, Brumgard says. Those additives could be difficult to find, or on back order when everyone wants them during widespread shutdowns, so make sure you plan ahead.

Brian Halstead, an application engineer at Castrol, recommends introducing some additional coolant concentrate just prior to an extended shutdown to ensure that your fluids maintain a high level of protection for your equipment.

“If you know that a shutdown will last longer than the week or two of a normal shutdown period, ramp up your concentration to a higher level than usual,” Halstead says. “Yes, you’ll have to add more water when production levels return to normal, but at least it gives you a cushion during the shutdown period.”

No. 3: Lab-Test Your Sump Coolant Fluids Frequently

A third important factor in maintaining your fluids during a shutdown is regular laboratory testing, Brumgard says. A few companies have the means to do this on-site, but many companies don’t, and it’s an important part of detecting bacteria growth.

Typically, a pH level of 8.5 to 9 indicates your fluid is alkaline enough to ward off bacteria growth, he says. If the pH level falls too low and the fluid becomes too acidic, pH adjusters should be added to help boost it.

There are biocides and fungicides that can be added, too, if lab results indicate the growth of bacteria and fungus in fluid samples. Brumgard recommends lab testing on a weekly or biweekly basis.

“You want to make sure you’re vigilant, even if you’re not at a high-production level,” he says. “If you’re overwhelmed by a biological attack, or you have rusted bolts, all your production processes that should have been easy are going to be much harder” when you resume production, he adds.

Halstead says shutdowns can be used as an opportunity for general fluid maintenance: clearing out areas in your sump where stagnant fluid or material can collect. It’s worth changing your filters, too, to improve general cleanliness.

“We recommend increasing filter media and cleaning out the systems more,” he says. That way, when production returns to normal levels, “you’re coming back to a clean system.”

Additives to Keep on Hand Following Extended Shutdowns

Here are three product additives you should keep stocked on-site when coming back from an extended shutdown:

pH Adjuster: Typically, you will see the pH drop in your fluid once bacteria is present. Using a pH adjuster will help you raise the pH of the fluid and make the environment less hospitable for bacteria growth.

Biocide: If bacteria are present in the fluid, first kill off all the bacteria in the system by adding a plant-approved biocide. Be sure to add it when the machine is in a high-circulation mode.

Fungicide: Fungus may grow during shutdown periods as well. Fungus differs from bacteria in that it isn’t present uniformly throughout the system. Instead, you will usually find it along the water line, at the filtration point or in areas where there is a high-splash effect.

Physically inspect the system prior to a fungicide addition. First, carefully remove any fungus and place it in a separate container for disposal to prevent further contamination. Once done, add a plant-approved fungicide.

Related Articles

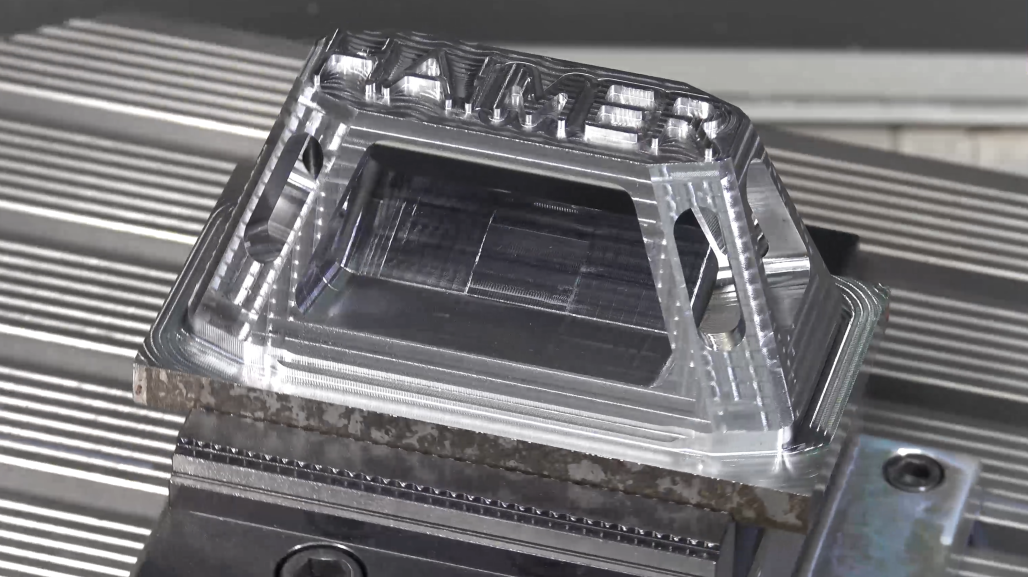

TOOLING UP: From Holder to Cutter: Inside HAIMER’s Full Tooling Assembly

Machine Troubleshooting Tips: Preventing Common CNC and Equipment Problems

Solid round tools - How it´s made