Kennametal delivers productivity to customers seeking peak performance in demanding environments by providing innovative custom and standard wear-resistant solutions, enabled through our advanced materials sciences, application knowledge, and commitment to a sustainable environment.

New ceramic grade delivers highest productivity when machining hardened steels, high-temperature alloys, and cast irons.

Kennametal has introduced its latest ceramic turning grade, KYHK15B™, designed to deliver increased productivity and lower cost per edge in hard turning operations. The new grade provides greater depth of cut capabilities than PcBN inserts when machining hardened steel, high-temperature alloys, and cast iron, as well as maximum tool life and wear resistance for the most demanding turning applications.

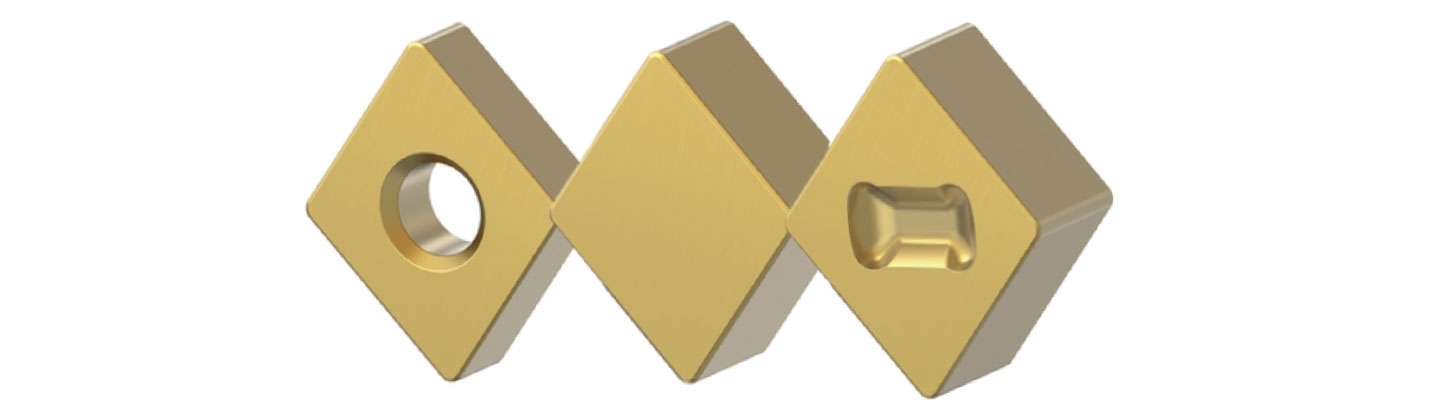

A broad range of styles, sizes, and edge preparations are available. These include the most popular styles of double-sided roughing and finishing inserts for predictable, cost-effective machining.

copy 3.jpg?itok=jDQ0Lywg)

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *