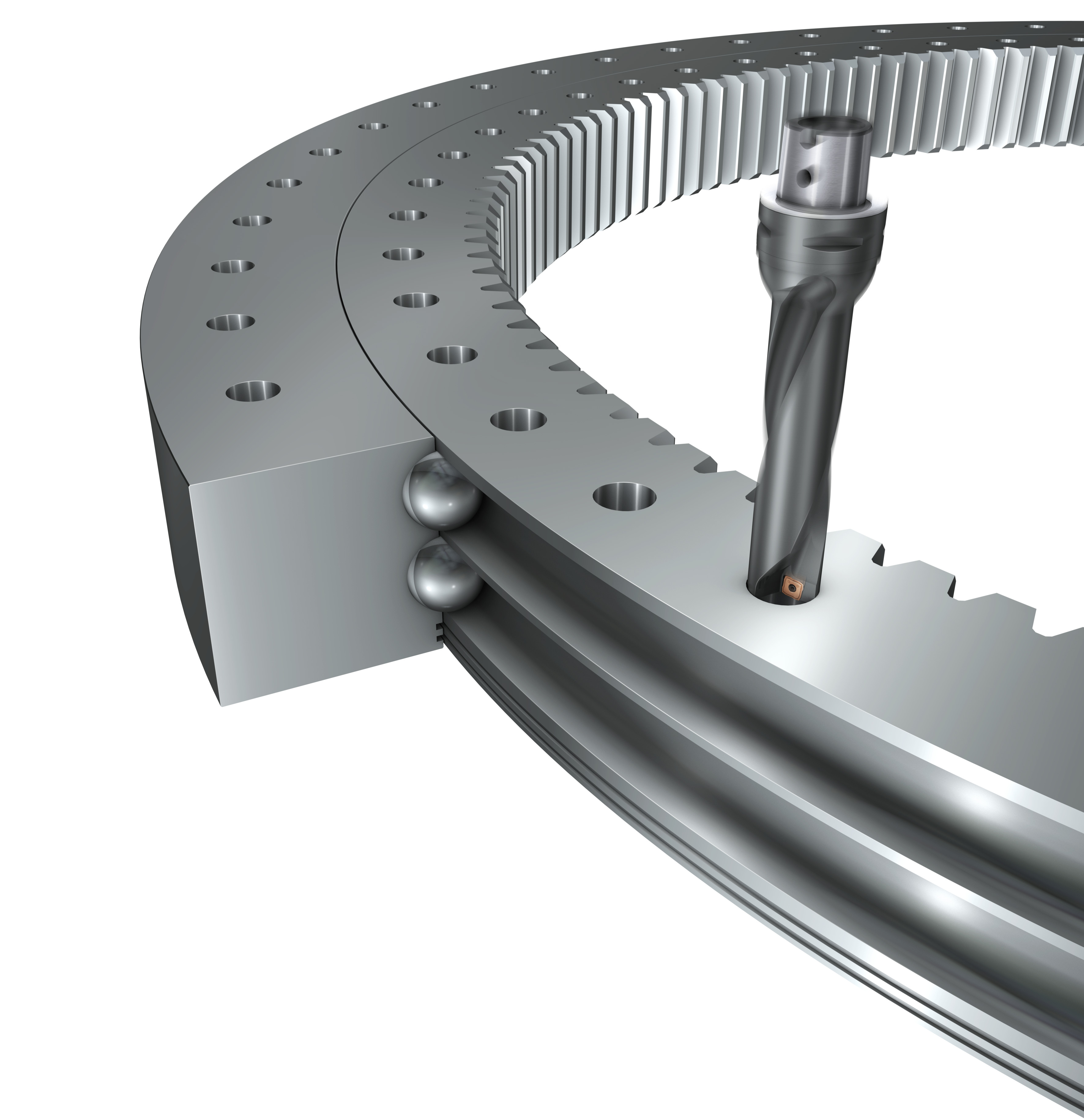

This indexable drill is designed for excellent chip evacuation. Strong drill body with central and peripheral inserts features unique Step Technology™ for a perfect cutting-force balance. With CoroDrill 880 high performance in most workpiece materials is guaranteed.

Drilling non-ferrous materials with ease

Since it takes less energy to accelerate a lighter object than a heavier one, lightweight materials offer great potential for increasing vehicle efficiency. A ten percent reduction in vehicle weight can result in a six to eight percent fuel economy improvement. Replacing cast iron and traditional steel components with lightweight metals, such as aluminum alloys or carbon fiber and polymer composites, can directly reduce the weight of a vehicle’s body and chassis by up to 50 percent and, therefore, reduce a vehicle’s fuel consumption.

Optimized solutions

The large variety of geometries and grades of the CoroDrill® 880 make it easy to find the right and optimized solution for most materials. The line features indexable insert drills from 12 to 84 mm (0.472–3.307 inch) in diameters with drill lengths of 2, 3, 4 and 5 × DC.

Non-ferrous materials contain soft metals with hardness under 130 HB, except for high strength bronzes (>225HB). Aluminum is one of the metals that belongs to this category. Pure aluminum is soft, ductile, corrosion-resistant and has a high electrical conductivity. When applied to an automotive body structure, it provides weight savings of up to 50 percent compared with the traditional mild steel structure. Such weight savings allow other vehicle systems to be downsized, including the engine, transmission, suspension and wheels. Making holes in aluminum can be a challenging task. Aluminum is difficult to drill because its ductility and softness cause the material to make constant prolonged contact with the cutting edges of a drill. The built-up edge that is generated by the adhering aluminum makes chip formation and evacuation difficult.

Demanding conditions

CoroDrill® 880 CVD diamond-coated insert grades N124 and N134 are specifically designed for demanding drilling in non-ferrous materials. This is where the insert coating combines the super hardness of a real crystalline diamond, providing long insert tool life. Together with chip breaker designs and a unique geometry, these inserts guarantee a superior performance in non-ferrous materials. Benefits include a low cost per hole due to long-lasting insert tool life and/or productivity increase. Due to reduced machine downtime with fewer insert changes, you’ll also see a boost in productivity. With easier handling in production due to the reliability of the inserts and longer insert tool life, you’ll see good hole surface finish resulting from great resistance to built-up edge.

Benefits of recycling

Aluminum can be recycled continuously with no loss of its qualities. Aluminum recycling benefits present and future generations by conserving energy and other natural resources. It requires up to 95 percent less energy to recycle aluminum than to produce primary metal and thereby avoids corresponding emissions, including greenhouse gases.

Shop Sandvik's CoroDrill® 880 here.

Brought To You By

Sandvik Coromant is the world’s leading supplier of tools, tooling solutions and know-how to the metalworking industry. With extensive investments in research and development they create unique innovations and set new productivity standards together with their customers. These include the world's major automotive, aerospace and energy industries.

More from Sandvik Coromant

More on Technology

Are you tightening your tools in an overtorqued death grip? Time to catch up with today’s technology and give your tools a breather.

President of Haimer USA Brendt Holden demonstrates how setting up your complete tool assemblies the same way every time can increase productivity and, in turn, save you time and money.

What manufacturers can do to deal with inflation.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *