Choosing the Right Abrasive Product for Welding and Metal Fabrication

Wondering which abrasive is right for your welding and metal fabrication project?

Wondering which abrasive is right for your welding and metal fabrication project?

Wondering which abrasive is right for your welding and metal fabrication project? Norton provides tips and a reference guide to help you make the right choices, in both the selection and usage of the product, so that you can minimize your costs and maximize your output.

What Is the Right Choice for Your Operation?

Tip: Start by Weighing Priorities

Abrasive products come in various levels of performance, which Norton labels "good," "better" and "best."

If initial price is your primary consideration, choose good abrasives; be aware that a lower purchase price up front may not end up being economical in the long run.

If you're running high-productivity applications and have to keep initial abrasive prices in mind, choose better abrasives.

If maximum productivity and lowest total cost are critical to your operation, consider the best abrasive products.

Tip: Test to Determine the Best Solution

When testing abrasive products, there are three measurements to consider:

Time

Material removed

Product wear

By holding one of these constant and measuring the other two, you can come up with an objective comparison between multiple products, helping you to find the best solution for your operation.

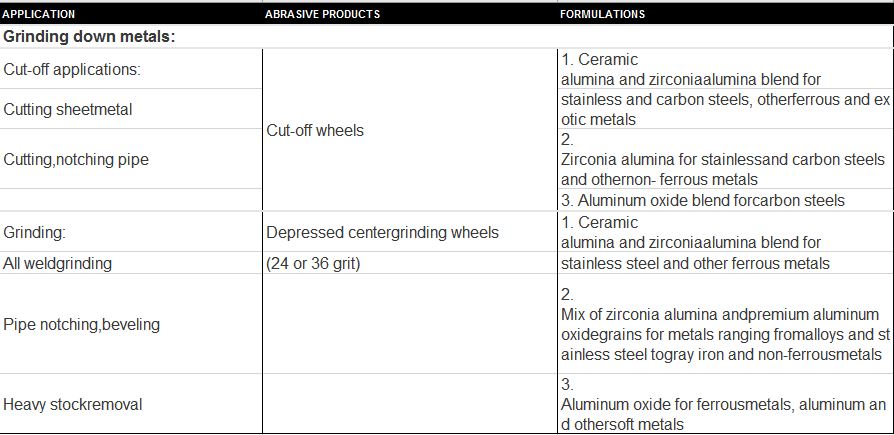

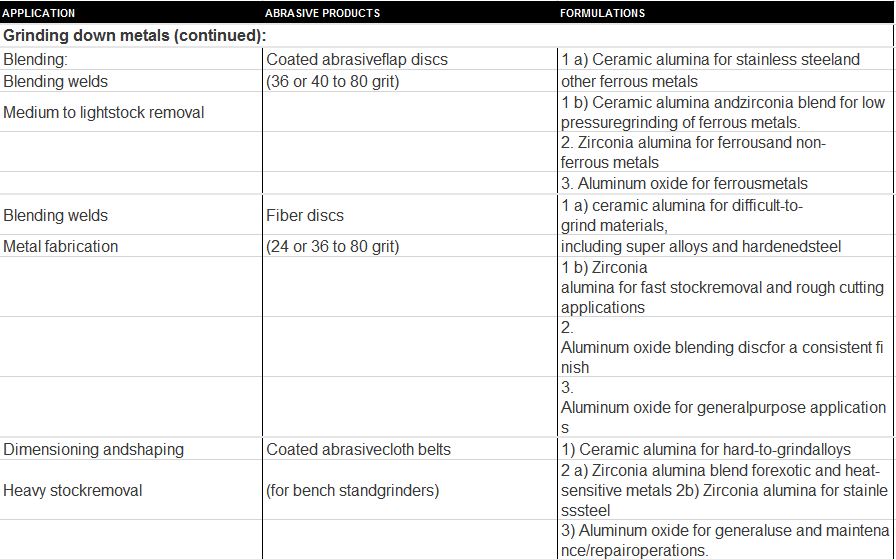

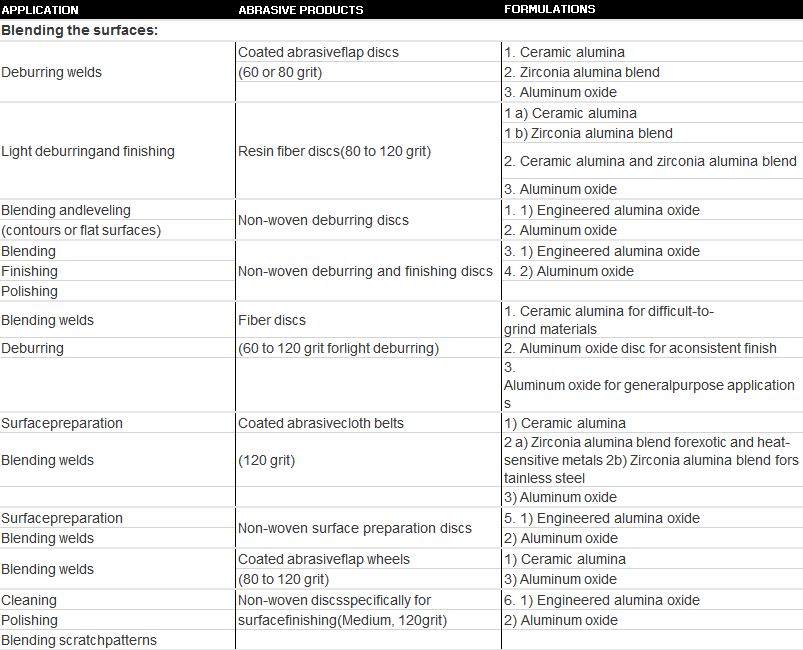

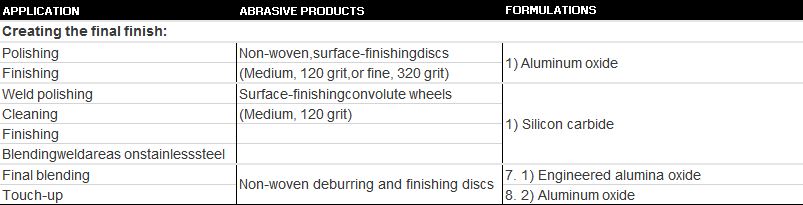

Abrasive Selection Guide

If you’re choosing an abrasive for welding and metal fabrication, refer to the guide below. Each application lists the relevant products in the order of best, better and good.

Tip: Use Safely and Maintain

Following safety and maintenance guidelines is very important and will also save time and money, contributing to the longevity of the abrasive, the production time, and the quality of the finished product.

For safety and maintenance information, check the manufacturer's catalog and product packaging. The manufacturing catalog will detail what products are designed for which machines, and some use icons to make the machine-to-abrasive match clear and easy. The product packaging also contains helpful information; mount it on your machine so your operators always have access to it.

We all want higher productivity and lower cost, but safety comes first. Start by making sure your operators take the appropriate safety precautions, and then use the correct abrasive products to get the job done right.

Previously featured on Norton Abrasives.

Shop Norton's selection of metal fabrication and welding abrasives here.

Founded in 1885, Norton grew into a global leader in abrasives before being acquired by Saint-Gobain in 1990. Norton offers the widest portfolio of grinding, cutting, blending, finishing, and polishing solutions for all markets, and applications using advanced, affordable technology. You get powerful, precise, easy-to-use options designed and engineered for optimum performance, cost and safety. Norton delivers choices that matter to your workforce, the environment, and your bottom line.