There’s been a tremendous amount of hype surrounding additive manufacturing (and 3D printing) in recent years. But is the technology really feasible for all manufacturers? It depends.

From body parts to houses, 3D printing, also known as additive in the manufacturing sector, has quickly moved from a headline-worthy tech fad for consumers to a viable, accessible means of building things, such as medical implants, automotive and aviation parts, and plastic prototypes for industrial designers.

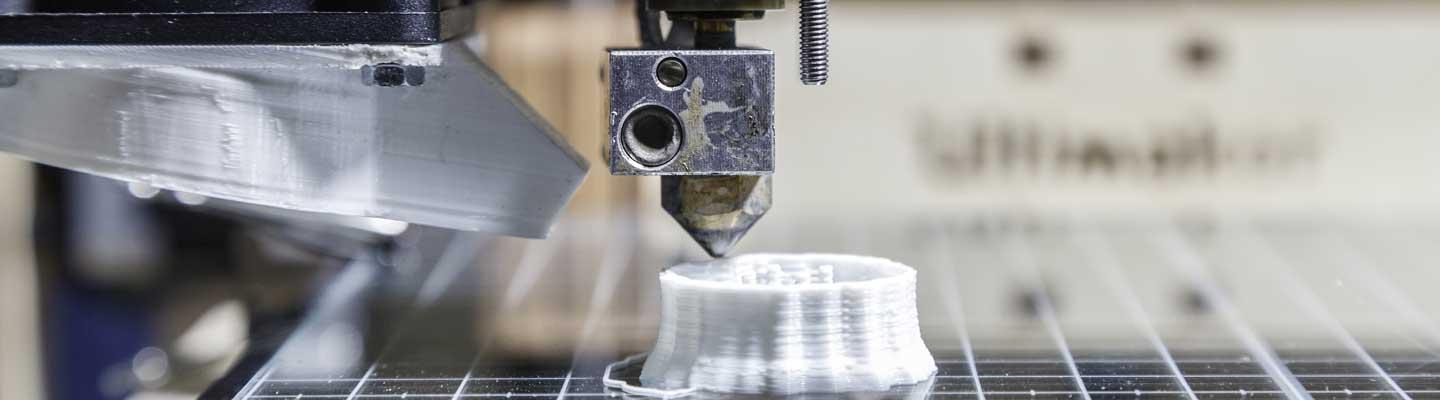

What is additive manufacturing exactly? The MIT Technology Review describes it as the industrial version of 3D printing where a machine “builds an object by adding ultrathin layers of material one by one.” Rather than traditional machining work that subtracts or removes elements from existing material (as in conventional metalworking, milling and CNC machining)—additive manufacturing builds from the ground up.

What are the benefits of additive manufacturing? It offers companies wider options to innovate and custom-tailor manufacturing to internal tooling and customer part and material needs—and to reduce costs by “decreasing the amount of material lost during fabrication, improving product yield, and/or reducing labor inputs,” according to Deloitte University Press in an article detailing 3D applications for tooling.

3D Printing: Additive Manufacturing Adoption Is on the Rise

According to a study from PwC and The Manufacturing Institute, roughly two-thirds of manufacturers have already adopted the technology in some form, and more than half are already using it for prototyping––a significant jump from only two years prior, with 35 percent of manufacturers trying out the technology.

And as the survey goes on to suggest, manufacturers assume that rapid growth surrounding additive will only pick up more speed. More than half of manufacturers expect additive manufacturing will be used for high-volume production within the next five years, compared to only 38 percent just two years ago.

The market for additive manufacturing for metals supports these findings. According to SmarTech Publishing’s “Additive Manufacturing with Metal Powders 2017” research, the market for additive manufacturing systems and metal powder materials was over $950 million in 2016—and is expected to grow to $6.6 billion by 2026.

3D Printing, Additive Manufacturing Challenges: Time & Cost

Despite the tremendous hype surrounding additive manufacturing, there are some limitations to understand. First, additive manufacturing can be slow to produce. Churning out the kind of volume you achieve with CNC machining in metals is not an apples to apples comparison.

“For metals, it is a different issue,” says Gordon Styles, founder and president of Star Rapid, in an interview with Engineering.com. “There is no point in 3D printing anything that is designed for CNC machining; it will naturally be a lot slower to print because the printing time is relative to the volume of material. Most metal parts designed for CNC are voluminous and therefore take a long time on a 3D printer.”

Several companies are working to expedite the process, notes Styles. But that improved technology will incite another sizable challenge for businesses: cost. Additive manufacturing can be pricey, so it is important to understand all the “cost levers,” finds Jason T. Ray, an advanced manufacturing industrial strategy consultant.

“Due to the novelty of AM [additive manufacturing] and high upfront investment costs required to buy the machines, the use cases often turn into a hammer looking for nails, rather than a cost-benefit driven process,” notes Ray in the article “Calculating the Cost of Additive Manufacturing” for Disruptive magazine. “When this happens, emphasis on redesign is reduced, and companies end up producing components that were originally designed for traditional manufacturing methods and thus only capture a fraction of the end-use benefits associated with AM.”

But as a report from the University of Nottingham found, that might not be the case forever. Their theory: As machine technology becomes more advanced, the economic case for adopting additive into production becomes more feasible. However, as long as machines stay the same, the cost will continue to remain high.

“While we are limited today, 10 years from now we will see hundreds of available materials,” Styles told Engineering.com. “The problem is not really the availability of materials, it is the time and effort required to switch materials. Today it takes about 24 hours to turn around a machine for a new material.”

However, there are some cases in which CNC machining could be costlier than additive manufacturing. But there’s only one surefire way to find out.

“The best way is to simply get a quote for the two processes from your rapid prototyping service provider,” Styles explains. “One rule of thumb, though, is this: If the part can be CNC machined, then it is probably cheaper to CNC machine it—and in 90 percent of cases, this is true.”

To top it off, Styles also highlights the fact that some additive materials could need further work from CNC machining, which would include removing supports. And what’s more, heat presents probably the most sizable problem of all, threatening to, quite literally, tear products apart.

“One must think of metal 3D printing as a liberating technology. You can now design seemingly impossible parts and still get them made, but the key is to keep the volume of material to a minimum.”

3D Printing in Factories: Plastic, Parts, Tooling, Hybrid

Challenges aside, when prototyping in plastic, additive manufacturing can have some major benefits. When CNC machining for prototyping with plastic, the issue lies in its cylindrical cutters, which make it difficult to machine the internal square corners that are common in these types of designs. With 3D printing, the opportunities for customization—and trial and error in prototyping—make sense for product, part and tool designers.

Additive manufacturing is “ideal for low volumes that need quick turnaround and benefit from savings in setup, tooling up and similar prep times even though the actual per part times can be much higher than with a purely subtractive process,” finds Bob Warfield, CEO and founder of CNC Cookbook, in an article about hybrid machining (where additive and subtractive processes coexist).

The Additive Manufacturing Case for Parts & Tooling

The real-world use cases for additive manufacturing are worthy of attention. Several of the major industrial manufacturers are taking full advantage of additive’s potential. Here are several examples from major industrial players.

GE expects to save money on the 25,000 fuel nozzles for LEAP jet engines it produces annually in several ways. First, additive techniques use less material during production. Conventional techniques required 20 parts to be meticulously welded—and they produced a ton of scrapped, wasted material, notes MIT Technology Review.

“[T]the decision to mass-produce a critical metal-alloy part to be used in thousands of jet engines is a significant milestone for the technology,” writes Martin LaMonica of MIT Technology Review. “And while 3D printing for consumers and small entrepreneurs has received a great deal of publicity, it is in manufacturing where the technology could have its most significant commercial impact.”

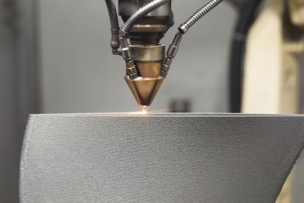

The additive process here uses hybrid-metal powders that are laser-sprayed to form, which makes the part lighter, leading to fuel savings for airlines. The process is cheaper to produce for the manufacturer—and the new part reduces the customer’s cost resulting in a true win-win.

In tooling, Deloitte makes a convincing case for additive’s use—detailing real-world examples where rapid prototyping via additive processes have significantly reduced lead times for castings and for internal tooling fabrication. Deloitte describes how Ford Motor Company has taken advantage of additive in a major way for its EcoBoost engines, rotor supports, transmission covers and brake rotors for the Ford Explorer.

“The company uses AM to rapidly create the sand molds and cores used for casting prototype parts,” notes Deloitte. “This has helped Ford reduce lead time by up to four months and has saved the company millions of dollars.”

The Case for Hybrid Machining: Additive and Subtractive

Speaking of hybrid, makers of additive manufacturing tools have begun to develop hybrid machines with both additive and subtractive abilities––and they’re quite a sight to behold. These “hybrid” machines pair the geometric freedom of 3D printing with the precise nature of CNC machining.

“Imagine a case where you need to do extremely low volumes of extremely sophisticated parts, for example, replacement parts for turbines in a maintenance facility,” writes Warfield. “A [hybrid] machine like this might just be ideal.”

However, with many of these new tools, manufacturers are limited to producing single parts and often can’t produce directly from digital files––something they’d be able to accomplish with solely additive strategies.

“One must think of metal 3D printing as a liberating technology,” stresses Styles. “You can now design seemingly impossible parts and still get them made, but the key is to keep the volume of material to a minimum.”

For large manufacturers, additive is making an impact. But even as Deloitte notes, that impact needs to be put in the right context of innovation:

“Currently, AM for the fabrication of tooling does not revolutionize supply chain or product design so much as it improves the efficiency and effectiveness of supply chains and products. However, as AM technology continues to improve and the use of AM for tooling continues to increase, it may gain the ability to impact companies’ supply chains and products more directly by increasing companies’ ability to innovate.”

Has your shop adopted additive manufacturing in full? What are some of your biggest challenges with the technology? Let us know in the comments below.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *