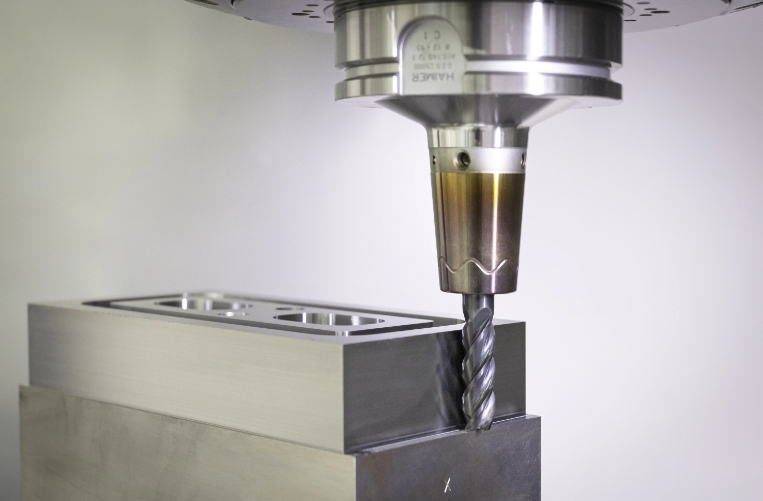

Haimer GmbH, the European market leader in the field of tool holding technology and system partner around the machine tool, has hit the bullseye with its universal solid carbide end mills of the HAIMER MILL family. For a long time, manufacturers, especially users in the areas of mechanical engineering, medical and contract machining, have been asking for a milling tool that they can use universally in steel and stainless steel, but also in cast iron, copper and even hardened steel for various operations. The HAIMER MILL tools, which are available as end mills according to DIN 6527 with sharp edge, corner radius or chamfer – showed substantial results in most of the cases. The same cutting edge geometries are available as modular tools for the HAIMER interchangeable head system, Duo-Lock.

Characteristics for HAIMER MILL end mills are the unequal cutting edge, the center cutting design and a neck for higher cutting depth. HAIMER makes quality their top priority: The end mills are supplied with an h6 shank tolerance and fine-balanced. The run-out accuracy is <10 μm.

To offer users even greater benefits, the family-run, medium-sized company from Igenhausen near Augsburg, Germany, has expanded the HAIMER MILL range even further. A short version with a cutting edge length of 1.25 x D is suitable for all applications that require less cutting depths. It perfectly uses the cutting edges at low ap values and achieves high stability. Designed without neck clearance and reduced shank length, the short HAIMER MILL version shows an unbeatable price-performance ratio like the standard version.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *