Accuracy and Calibration of Calipers

Mitutoyo addresses the accuracy and calibration of digital, dial and vernier calipers in this technical bulletin.

Mitutoyo addresses the accuracy and calibration of digital, dial and vernier calipers in this technical bulletin.

This unit of the Metrology Fundamentals series was developed by the Mitutoyo Institute of Metrology, the educational department within Mitutoyo America Corporation. The Mitutoyo Institute of Metrology provides educational courses, free on-demand training videos, and other resources across a wide variety of measurement related topics including basic inspection techniques, principles of dimensional metrology, calibration methods, and GD&T. For more information on the educational opportunities available from Mitutoyo America Corporation, visit them at www.mitutoyo.com/education.

This technical bulletin addresses the accuracy and calibration of digital, dial, and vernier calipers. The technical basis for this document is the American national standard (ANSI standard) entitled ASME B89.1.14-2018. This technical bulletin summarizes the most important technical issues; however, the ASME standard should be consulted for further information.

Two accuracy specifications cover the most important metrological characteristics of calipers. In accordance to the ASME standard, as well as the international standard ISO 13385-1, these two characteristics are called the partial surface contact error, E, and the scale shift error, S. The partial surface contact error applies to any measurements made using the outside measuring faces, and the scale shift error applies to measurements using any other measuring faces available on the caliper, such as inside, step, and depth measurement. The key difference is that all specifications apply when the zero is set using the outside measuring faces and therefore there is the possibility of larger errors when using the other measuring faces.

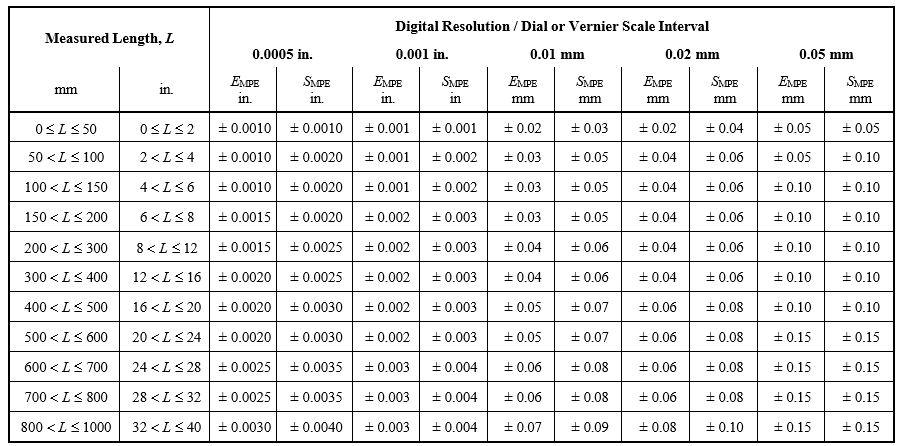

The table below lists the default specification values that are in the ASME B89.1.14 standard. These specifications are stated as maximum permissible errors, or MPE values, for the E and S errors. These values are only defaults – the manufacturer or user may state different values. Mitutoyo generally states values that are equal to or less than the values shown in this table. Mitutoyo specifications for calipers are quite similar to these values, and many customers may find the best practice is to simply adopt these values for their own caliper calibrations.

For complete definitions of _E_MPE and SMPE please see the ASME B89.1.14-2018 standard.

These specifications are a function of the measured length, L, not the overall measuring range of the caliper.

The decision rule that applies for these specifications is Simple Acceptance with a test uncertainty ratio, TUR ≥ 4.

All specifications apply at 20°C.

The most important aspect of the calibration of a caliper is to verify conformance with stated accuracy specifications. In accordance with the ASME B89.1.14 standard, the conformance verification tests for _E_MPE and _S_MPE are described below.

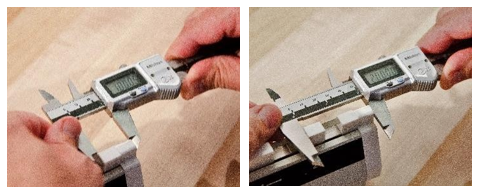

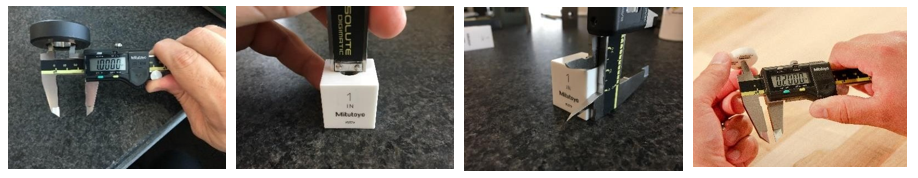

Using the outside measuring faces, conformance to _E_MPE is verified by measuring gage blocks, a caliper checker, or other reference standards across the measuring range of the caliper. A minimum of three to five test points is required depending on the measuring range of the caliper (see ASME B89.1.14 for details). At least 90% of the measuring range shall be covered. In addition, the reference standards shall be located at various positions on the measuring faces, from close to beam to near the tip of the jaws.

Conformance to _S_MPE must be verified for all the other modes of operation that are possible with the caliper with at least a single test point. The reference standard for testing the inside measurement is typically a caliper checker, a ring gage, or gage blocks and accessories. The default size for testing is between 0.75 in (20 mm) and 2 in (50 mm). For depth and step measurements, the reference standard is typically a gage block on a surface plate. A square gage block provides a useful hole to insert the depth bar. By default, the size for testing shall be less than 2 in (50 mm).

The internal measuring faces on many styles of calipers use crossed knife-edges. Due to the thickness of the faces and the clearance between them, additional errors can occur when measuring small internal diameters. For calipers that utilize cross knife-edge measuring faces, ASME B89.1.14 requires an additional test using a 0.2 in (5 mm) diameter ring gage for all calipers with measuring ranges up to 12 in (300 mm).

The selection of the test points should be considered carefully when calibrating calipers. ASME B89.1.14 defines general rules but also allows the user/customer to select the test points. In cases of used calipers, there may be times where cyclic errors may occur, e.g. on dial calipers the test points should orient the pointer at various angles within the dial. In addition, for used calipers, the condition of the measuring faces should be checked carefully for wear (see details in ASME B89.1.14).

The Mitutoyo Calibration Laboratory in Aurora, Illinois, offers accredited calibrations (A2LA 0750.01) of calipers as well as all the measurement standards needed to calibrate calipers. The Mitutoyo Calibration Laboratory is the premier dimensional calibration laboratory in the United States. Customers are welcome to visit and tour the Calibration Laboratory. Contact 888-MITUTOYO or email calibration@mitutoyo.com.

In addition to offering the most complete line of dimensional measuring equipment and solutions, as well as the highest-level commercial calibration and inspection laboratory in North America, Mitutoyo America Corporation offers educational courses, customized on-site seminars, and online educational resources. Find out more at www.mitutoyo.com/education or email mim@mitutoyo.com.

Previously Featured on Mitutoyo's Resources page.

Established in 1963, Mitutoyo offers a full product line of precision measuring tools including calipers, micrometers and indicators, as well as instruments and equipment. Mitutoyo is the leading metrology company in the world and is committed to developing breakthrough technologies for its comprehensive range of dimensional measuring tools, instruments and systems. Mitutoyo continues to develop the most advanced and sophisticated metrology equipment available.