The diverse abilities of multitask lathes are pushing many machining businesses to reconsider their CNC machine tool selection. Here are five reasons why one of these machines should be your wingman on the journey to greater machining efficiency.

For as long as there’ve been machine tools, the people who own and operate them have yearned for equipment able to perform turning, milling, grinding and even gear-cutting operations equally well in the same machine. Such all-in-one machining platforms would greatly simplify the manufacturing process, they argued.

Work-in-process would be reduced. There’d be far fewer secondary processes and their associated fixturing costs. And because multiple part features or even the entire part might be completed in a single operation, part accuracy would be greatly improved. What’s more, there’d be no sacrifices in milling rigidity as there are on mill-turn lathes, or the admittedly lukewarm turning speeds achieved on “turn cut” capable horizontal machining centers and those with U-axis turning heads. As a result, neither tool life nor productivity would suffer.

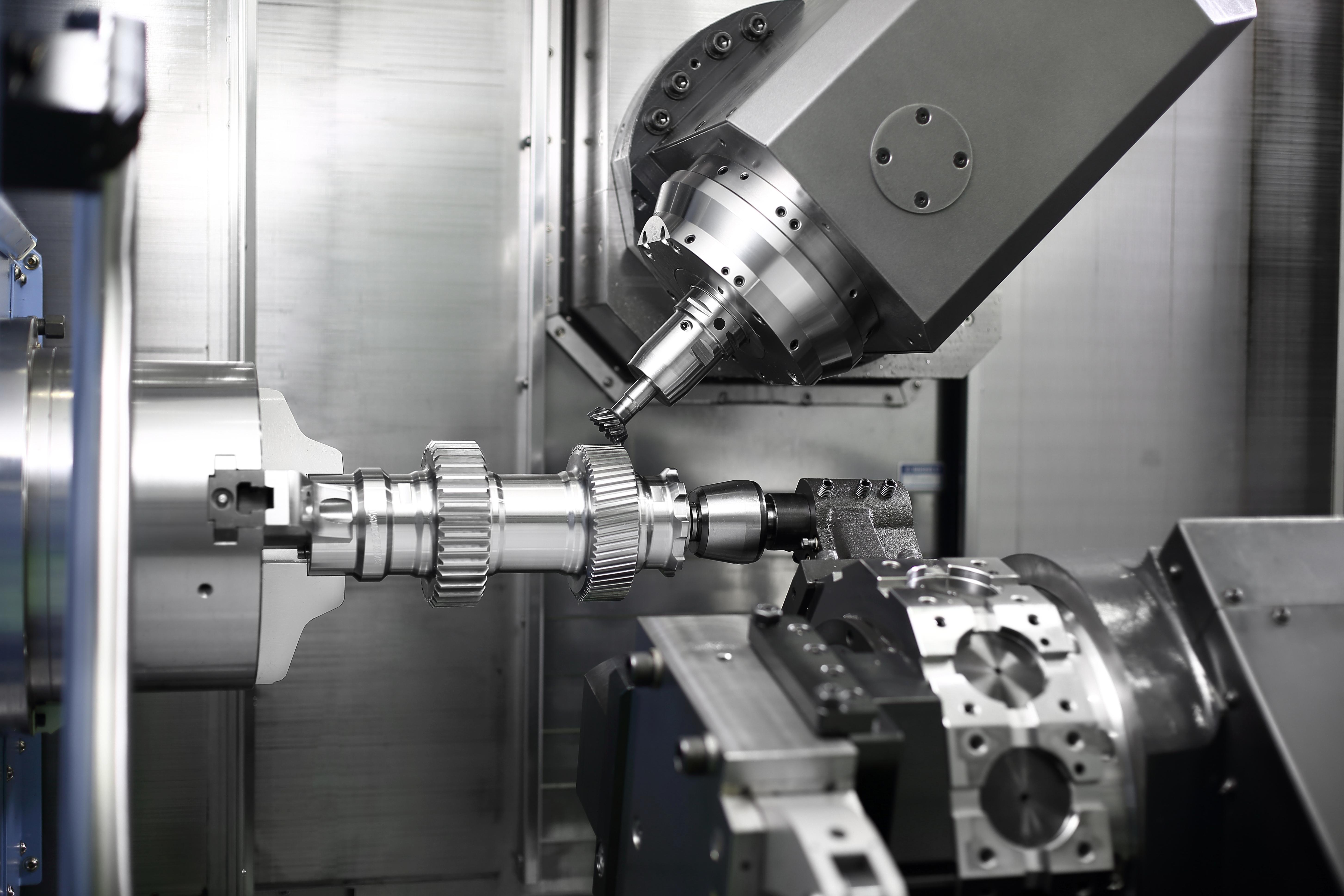

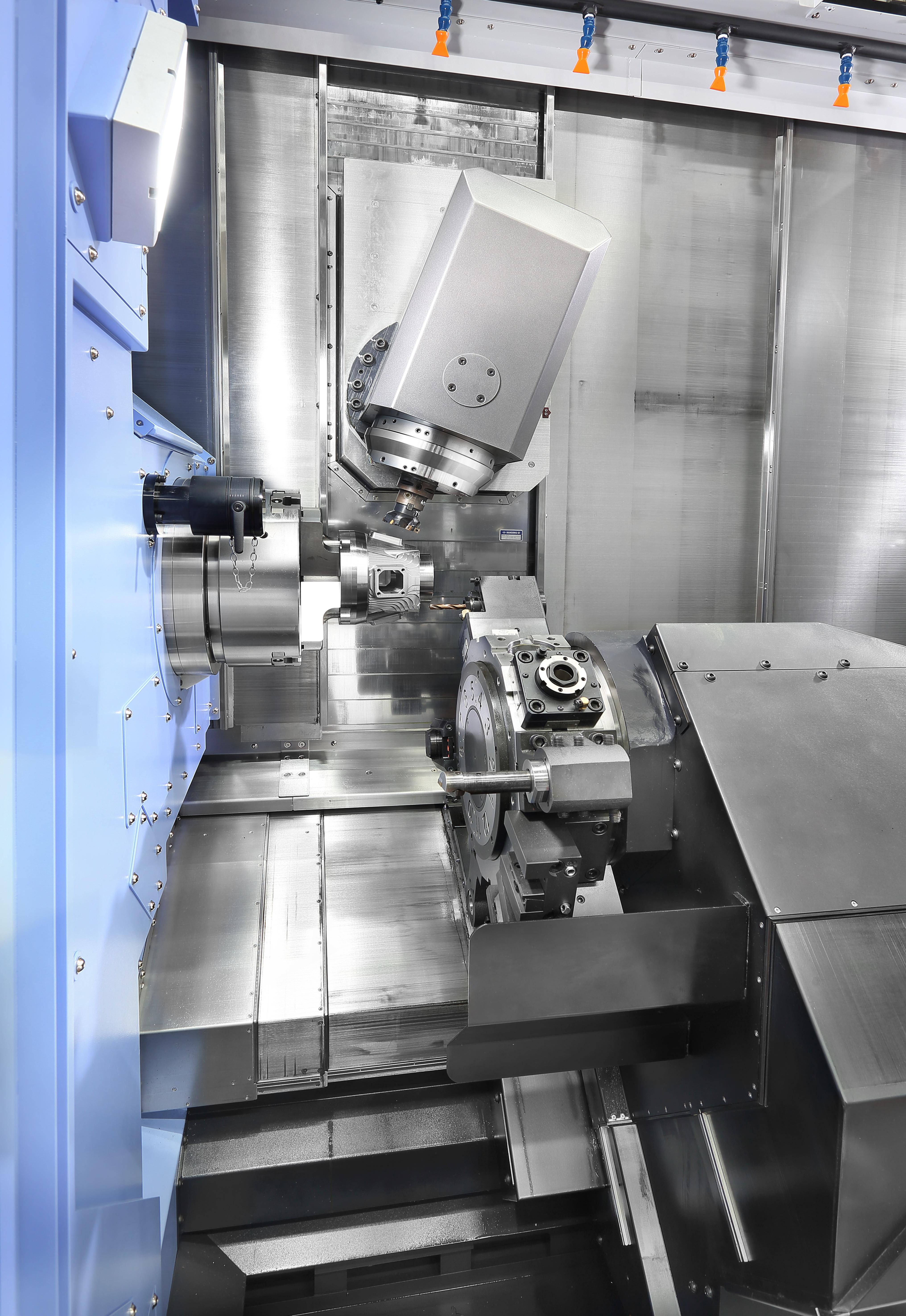

The wait is over. Today’s multitasking CNC lathes meet each of these goals at a price tag within reach of even the smallest machine shop. Construction varies from builder to builder, but most multitaskers come equipped with a pair of opposing lathe spindles, a swiveling machining center-style milling head, and an automatic tool changer (ATC). Some boast a lower turret, but it’s the dual-function milling spindle and tool-changing capabilities that separate these highly flexible machine tools from their more production-oriented mill-turn and Swiss-style lathe relatives.

Need proof? We asked three leading machine tool manufacturers why someone should make the leap to multitasking. Given the fact that all of them offer true multitaskers as well as live-tool, turret-style lathes, their answers might surprise you.

No. 1: Maximum Milling

Doosan was among the first to introduce milling capabilities on its Lynx and PUMA series 2-axis CNC lathes. Doing so provided many of the same benefits mentioned earlier, such as improved part accuracy and the elimination of secondary operations. But as Andy McNamara notes, neither his nor anyone else’s live-tool lathes can mill at the same level as a multitasking machine.

“There’s no apologizing for a multitasker’s metal removal capabilities,” says the director of sales at Doosan Machine Tools America. “They use a real machining center-style head, not a bolt-on rotary attachment. That means they’re more rigid, they generally spin much faster, and have far longer duty cycles.

Add to that an HSK, Capto (PSC), or similarly robust dual-contact spindle interface, and you have the best of both worlds in terms of turning and milling.

Read more: 5 Ways Manufacturers Can Use Data Analytics to Improve Efficiency

No. 2: Twice the Turning

McNamara says this same statement often applies to a multitasker’s turning capabilities. Because most eliminate the traditional main and subspindle construction found on mill-turn machines in favor of opposing main spindles, there are no sacrifices in power, speed or capacity. And as Jason Smith, national sales manager of production turning products at Absolute Machine Tools points out, the addition of a lower turret or—in the case of the company’s QuickTECH models, a gang-type tool block accessible to the right-hand spindle—serves to reduce cycle times.

“As with a mill-turn or Swiss-style lathe, this allows you to perform machining operations on each spindle simultaneously,” he says. “A fixed gang plate also eliminates the situation where chips pile up on the lower turret, which can lead to recutting or the need to stop the machine periodically for chip removal. And because the right-hand spindle moves on its own Y-axis and can drop down out of the way, there are fewer interference issues with the upper head.”

No. 3: Shortened Setups

Smith and McNamara agree that, despite the often impressive complexity of parts produced on multitasking lathes, setup times can be surprisingly short.

David Fischer, lathe product specialist at Okuma America Corporation, attributes this to the presence of an ATC. This lets the shop set up dozens or even hundreds of tools and leave them in the machine, making multitaskers ready to take on whatever comes their way—just upload a program, change the workholding, and go.

“I worked with a customer recently that needed eight hours to set up a multiaxis mill-turn machine,” he says. “For years they’d been producing job quantities of 1,000 pieces or more so were able to amortize setup-related downtime over a fairly large number of parts. The problem was, a lot of their production quantities were falling into the 60-to-100-piece range, just as they are in most shops. So we moved the shorter-run work to one of our MULTUS machines. And although it took longer in some cases to actually machine the parts, the setup times were so short that they were halfway done with the batch before the other lathe even started production.”

No. 4: Better Accuracy

Each expert agreed that multitaskers provide another important benefit, although it’s one that’s also shared by mill-turn centers, or indeed any machine tool able to complete most or all of a part in a single operation. Because there’s less moving of parts from machine to machine for secondary operations, accuracy is significantly improved. This is critical where tight geometric tolerances exist, or where squareness, concentricity or parallelism between part features can be jeopardized by the need to position a turned part in a milling fixture, and vice versa. Nor is there the risk of part damage due to clamping forces or small chips that stick to a locating face, thus denting the workpiece. Work-in-process is similarly reduced, as are lead times and fixturing costs. In addition, multitaskers help avoid the painful situation where an entire batch of parts gets scrapped out on a downstream operation and must be re-machined from scratch.

Read more: Medical Machining: Cutting Tool Manufacturers Offer Insights, Advice for Success

No. 5: Less Operator Intervention

“I don’t think people appreciate the value of completing parts in a single operation,” Fischer says.

“Instead of three, four or five handlings like there is with conventional processing, the part often comes out finished, ready to ship. There are no surprises or chances for human error. It also gives operators uninterrupted time to do other, more important tasks than standing in front of a machine all day. They can get the next job ready, for example, or tend another machine,” he says. “Contrary to what some might think, I’ve never viewed multitasking and other highly automated machining processes as taking work away from a person, but rather as letting machines do what machines do best and letting people do what people do best. The uninterrupted cycle time also makes it much easier to run lights-out, a factor that can easily justify the higher price of a multitasking lathe.”

Despite the many benefits, everyone here agrees that multitasking isn’t a one-size-fits-all solution. With parts requiring heavy turning and no milling, for instance, a basic 2-axis or twin-turret lathe is probably a better solution, especially where larger job quantities are involved. Similar arguments can be made for flat plates, hydraulic valve bodies and other orthogonal parts best suited for a vertical or horizontal machining center.

The Ticket to Success

And don’t forget the earlier comment about multi-turret, twin-spindle turning centers and Swiss-style lathes—although they typically take much longer to set up, it’s tough to beat the cycle time of a machine tool able to perform two, three or more operations simultaneously.

The bottom line: Be sure to explore all your options when purchasing your next CNC machine tool. A multitasking lathe might be the ticket to success.

Have you adopted multitask lathes in your shop? What challenges or successes have you faced? Share your thoughts in the comments below.

Related Articles

The Latest Tools and Techniques in Metal 3D Printing

HOW TO Put Innovation to Work for You

VIDEO: HOW TO Implement Grinding Solutions with Automation

Smart Restrooms: Companies See Value in IoT Connected Dispensers