Industry 4.0: New Digital Tool Management System from HAIMER

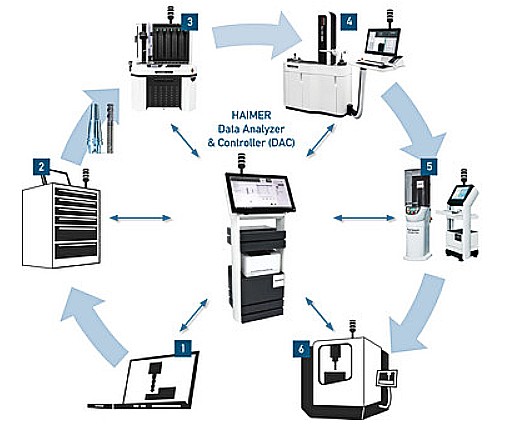

HAIMER's DAC (Data Analyzer and Controller) is a digital tool management system that connects the entire tool room to a digital Industry 4.0 system.

HAIMER's DAC (Data Analyzer and Controller) is a digital tool management system that connects the entire tool room to a digital Industry 4.0 system.

Pick up any machining or manufacturing publication and you will likely find an article on Industry 4.0 (i4.0). Simply put, i4.0 is the digitalization of the manufacturing process by connecting machine tools with networks so data can be shared and analyzed.

In the machine shop of the future, balancing, presetting, shrink fit equipment and machine tools will interface and communicate with each other. The visualization of this data will make the entire enterprise more efficient and productive.

HAIMER has already embraced i4.0 and is currently setting new standards for digital connectivity and communication between tools and machines. This forward thinking is reflected in the i4.0 generation of their proven Power Clamp shrink fit machines: The Premium i4.0, Sprint i4.0 and Comfort i4.0. As the names suggest, they are all industry 4.0-ready and network-compatible.

Their latest example of i4.0 technology is the HAIMER DAC (Data Analyzer and Controller). This digital tool management system enables a consistent exchange of tool data, and connects the entire tool room (including CAD/CAM and the machine tool) to a digital Industry 4.0 system.

The DAC establishes the connection with a corporate network and manages the exchange of target and actual values (as well as other tool data) between the individual tool room stations.

The complete tool – HAIMER tool holders in combination with available RFID data carriers, QR or data matrix codes (which can be read and evaluated by various systems via a scanner) – can be clearly identified.

Through the network connection, the DAC also provides additional tool data: assembly instructions, article numbers, stock adjustments, and 3D models. The DAC also supports the user in the analysis of production data and process optimization.

In the CAD/CAM system, a tool assembly order is generated and sent to the DAC, which generates a tool ID which accompanies the tool throughout the entire process for traceability. The subsequent stations – assembly (e.g., shrinking), measuring and balancing – all communicate with the DAC.

After the last value transfer, the data is sent to the machine tool control, where the correct magazine location is specified. Potential confusion regarding the correct magazine location can be prevented by scanning the tool ID at the machine.

Depending on the unbalance tolerance, an adaptation (such as reduction) of the maximum spindle speed takes place, if necessary. After the milling operation, data on the remaining tool life is transferred back to the DAC.

The system is easy to operate: The user controls the entire process by simply clicking and confirming (data transfer). Since no manual input is required (or even possible), there is no false input, and thus no collision risk. The HAIMER DAC concept is scalable from small to large and makes digitization in tool management feasible for small and medium-sized companies as well as larger organizations. The customer can take over existing machines and systems, as these can also be integrated by the DAC.

If you would like to get a jump on Industry 4.0 for your machining operations, contact HAIMER and they'll set you up with a system that is way ahead of its time.

Previously Featured on HAIMER's blog.

Haimer is a globally recognized leader in premium tooling technology, specializing in solutions, mainly for the metalworking industry. As a German manufacturer, Haimer is dedicated to delivering exceptional quality across its product range, which includes shrink fit tool holders, collet chucks, shrink fit machines, carbide end mills, balancing machines, tool presetters, and 3D sensors. At Haimer, quality is the cornerstone of success: QualityWins.