Innovative practices can help you overcome the challenges you face in metalworking

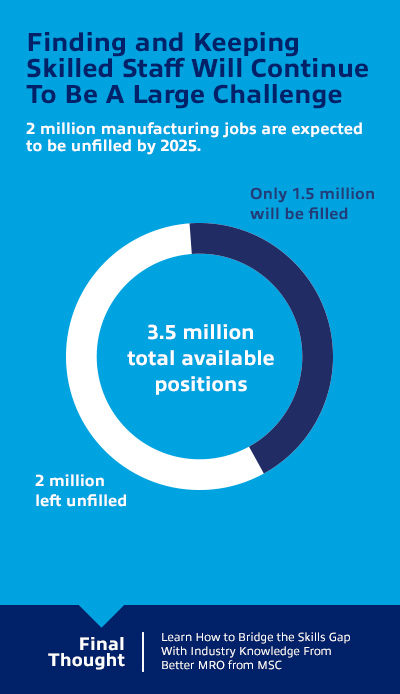

If you’re like most professionals in operations, plant management or engineering, you face a range of challenges. Increased use of lightweight materials, ever-shrinking lead times and fluctuating raw material costs are just some of the hurdles that impact daily operations and overall profitability. Then there are the staffing challenges you face — finding skilled metalworking professionals is hard, and keeping them is even harder.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *