Documenting Results

Documented cost-savings programs have become increasingly popular in recent years and in some cases are a requirement.

Documented cost-savings programs have become increasingly popular in recent years and in some cases are a requirement.

Fabricators and welders are likely aware of using documented cost-savings initiatives as a way to satisfy requests for proposals and purchases. Documented cost-savings programs have become increasingly popular in recent years and in some cases are a requirement.

In a drive to reduce operating costs, some customers try to purchase cheaper products while others require their distributor to provide them with a cost-savings analysis. For the distributor, it is not uncommon to have documented cost savings as a requirement for compensation by its customers. If you are not already using documented cost-savings programs, it is advantageous to understand what these programs look like and what they can do for you.

Watch this short video to learn more about Starrett's Intenss Pro bi-metal bandsaw blade.

Documented cost-savings programs may consider multiple elements, but the cost of the product is a primary consideration. The documented cost savings form has the current product as well as the new product being tested, and the product may be tested anywhere from a few minutes to its full lifespan.

For example, when calculating the cost savings of a bandsaw blade, counting the number of cuts in an allotted time frame and running a calculation provides the estimated cost-per-cut ratio of each with an annualized product savings. However, some programs, such as the cost-savings program offered by The L.S. Starrett Co., take this a step further and consider potential labor savings. This is where the real savings emerge.

In a real-world application using bi-metal bandsaw blades, Starrett ran a cost-savings test for a customer that was cutting 19-in. round steel material.

During the test, Starrett ran the same parameters of 121 ft. per min. from the previous blade so the change in longevity could be measured. It’s imperative that only a single variable is changed at a time to accurately measure the performance of the variable you wish to change. That variable could be cutting speed, flatness, roughness average or longevity.

In the case of the customer cutting 19-in. steel, increasing blade longevity was the goal. Starrett was able to add an additional 2.75 hours of blade life in the application, increasing it from 5.5 to 8.25 hours. When factoring in the labor to change the blades on an annual basis, the increased blade life and the decreased blade cost, Starrett was able to document savings of $185,000 per year for the customer.

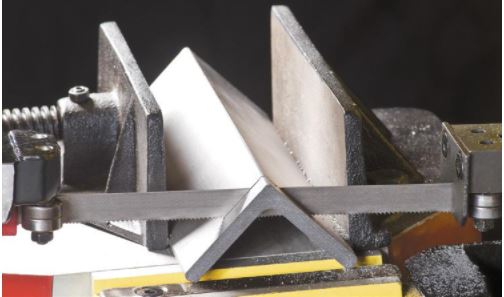

Starrett’s Versatix MP is a bi-metal bandsaw blade of triple-tempered, high-speed M42 cobalt steel teeth that has a patented tooth design that dissipates stress during cutting for less tooth breakage and longer blade life.

With an understanding of the anatomy of cost-savings tests and what they measure, why do you need to document these programs, rather than simply try out new products? There are a few reasons that documentation is vital.

When a new purchasing manager comes to a company, familiar patterns of product purchases and preferred vendors are also brought to the table. This could be beneficial, but in many cases it is not optimal or based on timely analysis. The same thing happens with operators where there is an industry-wide struggle to keep skilled talent long term. Each may come with their own ideas and preferred products, and due to high employee turnover, a manufacturer may find itself with cabinets or tool cribs full of products that are rarely or never used.

By documenting the cost-savings testing, files will exist of the best product for the job and the associated costs. Rather than taking recommendations based on pre-conceived rationale, each request can be approached systematically and real data can be used to drive decisions.

At the end of the fiscal year, when a customer or your company asks for an annual assessment review, you can show them all the savings you created. For example, by understanding the importance and gravity of labor costs, you may identify speed of completing a job as the most vital variable to change, even when there may have been an increase in the cost of the product during the year. By means of documentation, you can show that although you spent more on product, you increased productivity by a measurable amount and, as result, saved thousands in labor.

By using documentation and data to drive effective and meaningful change, it is easier to prove to a purchasing agent or continuous improvement manager how product cost may be less important data.

Finally, when it comes to review time, this is great leverage that demonstrates the important contributions you make to the company.

By systematically running a documented cost-savings analysis, a change in technology may be in order rather than continuing to use obsolete or ineffective equipment. An operator may resist change and be hesitant to consider new tools and vendors. However, a cost assessment can provide real data for making the transition.

In this regard, Starrett offers documented cost-savings programs for a range of cutting requirements for fabricators and welders as well as for high-production sawing jobs. Highly specialized Starrett saw specialists, territory representatives or product managers can come to your jobsite to do a full evaluation from start to finish.

Dedicating some time to run cost-savings tests can result in dramatic savings that can protect your company in a virulent market or increase cash on hand for further growth and investments. Take out the guesswork with supporting data that tells a story of empirical fact, not anecdotal opinions.

Previously Featured on Sawing Productivity digital magazine.

Laroy S. Starrett was an innovator and entrepreneur who wanted 'to invent something useful that people would want.' In 1880 he founded The L.S. Starrett Company with his patented design of the combination square with the goal to put his tools in the hands of hard-working American craftspeople. Today, the company manufactures over 5,000 varieties of precision tools, gages, measuring instruments, and saw blades for industrial, professional, and consumer markets worldwide.