To help you establish a safer, more compliant electrical safety program, Brady’s electrical engineers target and evaluate key areas covered under the 2015 NFPA 70E Standard. Take a look at the following questions to determine your progress and tasks needed to help mitigate electrical risks and continuously improve your current state.

Establish a safer, more compliant electrical safety program.

HAVE YOU HAD AN ARC FLASH RISK ASSESSMENT?

YES — Under NFPA 70E, Arc Flash Risk Assessments must be:

- Reviewed periodically at minimum every 5 years

- Updated when a major modification or renovation takes place

NO — NFPA 70E Requires that an Arc Flash Risk Assessment be performed and shall:

- Determine if an arc flash hazard exists. If it does exist, the risk assessment will determine appropriate safe-related work practices, arc flash boundary and PPE to be used within the arc flash boundary.

- The results of the risk assessment must also be documented.

HAVE YOUR EMPLOYEES RECEIVED ARC FLASH TRAINING WITHIN THE LAST THREE YEARS?

YES — NFPA 70E 110.6(E) requires that all training must be documented and employees must show proficiency. NFPA 70E 110.2(D) requires employees to be given additional electrical safety-related work practices every three years. Employees must be retrained before performing any tasks that are performed less often than once per year. And Article 100.6 (D)(3) requires that an employee must be retrained or receive additional training:

- If the supervisor observes, or annual inspections reveal, that the employee is not following the rules and regulations.

- If new technology, new types of equipment or changes in procedures necessitate the use of safety-related work practices that are different from those the employee would normally use.

- If the employee must use safety-related work practices that are not normally used during his or her regular job duties.

NO — NFPA 70E 110.2(D) requires employees to be given additional electrical safety-related work practices every three years. Employees must be retrained before performing any tasks that are performed less often than once per year. And Article 100.6 (D)(3) requires that an employee must be retrained or receive additional training:

- If the supervisor observes, or annual inspections reveal, that the employee is not following the rules and regulations.

- If new technology, new types of equipment or changes in procedures necessitate the use of safety-related work practices that are different from those the employee would normally use.

- If the employee must use safety-related work practices that are not normally used during his or her regular job duties.

Nice work completing the initial checkup. Grab your current arc flash label and check out the comprehensive label guide on the back to help you comply with 2015 NFPA 70E.

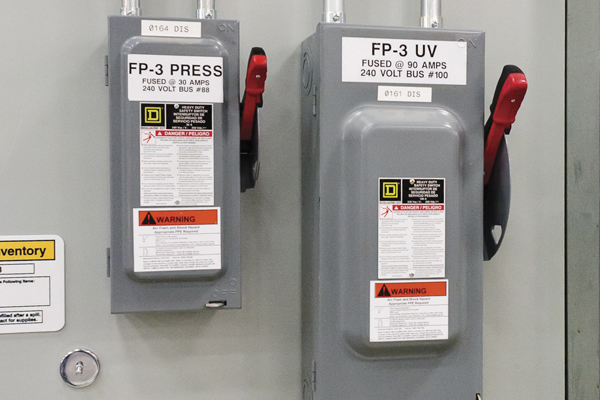

When looking at your best practice label you should see:

- Incident energy and corresponding working distance

- Arc flash and shock hazard boundaries

- Device name

- Level of PPE

- Nominal system voltage

Anything above 50V that could be worked

on while energized, resulting in exposure to

electrical hazards, requires an arc flash label.

Visit BradySafety.com for more information.

Brought To You By

It takes a lot to get it right. To be a company that lasts more than 100 years by continually evolving and growing to meet the needs of our markets and customers. Our first-to-the-market and best-in-the-market approach led us to receive hundreds of patents over the years and truly shape an industry. We do what others don't in ways they can't. We offer innovative products backed by years of research and development. Beyond our quality products and reliable solutions, we add value for our customers through strong partnerships and a commitment to solving important problems. Brady offers solutions to help increase safety, security, productivity and performance throughout your facility—everything from printing systems, software and high-performance labels to facility signs, safety devices, expert safety services and more.

More from Brady

More on Regulatory Compliance

With the introduction of a new industrial bump cap standard, safety professionals have a new tool to address a critical gap in workplace head protection.

Proper illumination in manufacturing facilities keeps workers safe and productive, and the company in compliance. Here’s what you need to know about industrial lighting standards.

When it comes to evaluating the protection levels of work gloves, two major industry standards are recognized worldwide: ANSI/ISEA 105-2016 and EN 388:2016.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *