Pioneers of metalworking coolants, Master Fluid Solutions®, has led the industry with uncompromised integrity, expertise, innovative technology, and environmental awareness since 1951. Master Fluid Solutions is the world leader in aerospace-approved metalworking fluids and continues to develop its TRIM® product line of synthetic, semisynthetic, neo-synthetic, and emulsions. Our product line is trusted by leading aerospace manufacturers with over 100 approvals and counting.

TRIM products are used to produce components found throughout an aircraft. In the engine, grinding the blades and vanes utilizes state-of-the-art synthetic coolant TRIM® C70, which provides excellent cooling, outstanding tramp oil rejection, and superior cleanliness. TRIM® HyperSol™ 888 NXT is used to manufacture the disks in the engine. This versatile, neo-synthetic provides exceptional performance on hard aerospace metals and superior lubricity necessary for machining harder titanium and nickel alloys.

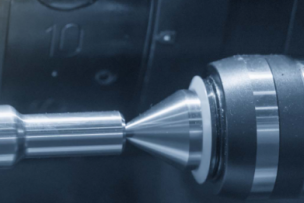

Engine shafts and other components are produced with TRIM® MicroSol® 585XT, a high-lubricity semisynthetic microemulsion. This coolant is low foaming with outstanding cooling and lubricity when turning, drilling, and tapping hard-to-machine alloys. TRIM® MicroSol® 590XT is used in the production of engine rings and cases. This environmentally friendly, semisynthetic, microemulsion coolant is specially formulated to pass aerospace approval test requirements. To manufacture the main gear piston in the landing gear, TRIM® OE315 NS is utilized. This heavy-duty, neat cutting oil is formulated using renewable vegetable esters. It is designed for use in very tough machining operations of heat-treated steels and ensures a long tool life.

A European Tier 1 manufacturer of landing gear pins and links increased their tool life by 234 percent with HyperSol 888NXT. A U.S. based aircraft components manufacturer saw a 50% reduction in coolant spend by switching to MicroSol 590XT from their traditional aerospace cutting fluid. An aerospace manufacturer created an estimated 30 percent reduction in coolant-related costs year over year with MicroSol 585XT. MicroSol 590XT reduced coolant usage by 50 percent and saved an aircraft components manufacturer over $500,000 in coolant costs annually.

• Our latest technology fluids are approved by all major aerospace OEMs

• Our MicroSol fluid technology runs cleaner with lower carry-off when compared to other common aerospace-approved products on the market

• Longer sump life and lower carry-off yields significantly lower product usage over time

• Our lower product usage and inherent recyclability lowers product disposal costs

• Our cleaner-running products yield dryer chips in the bin, increasing the value of the chips.

The TRIM products shown in this video are examples, and are great models of how these metalworking fluids can improve your aerospace manufacturing operation. Master Fluids Solutions has a wide range of coolants available within its portfolio, with multiple approved products that can be used for each aircraft part. Please speak to a District Sales Manager today to find out more.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *