VIDEO: HOW TO Turn a Supplier into a Partner

Join Jacob Sanchez in this episode of MSC Industrial Supply's "How To" series as he explores how Walter America builds strategic partnerships beyond traditional supplier relationships.

Join Jacob Sanchez in this episode of MSC Industrial Supply's "How To" series as he explores how Walter America builds strategic partnerships beyond traditional supplier relationships.

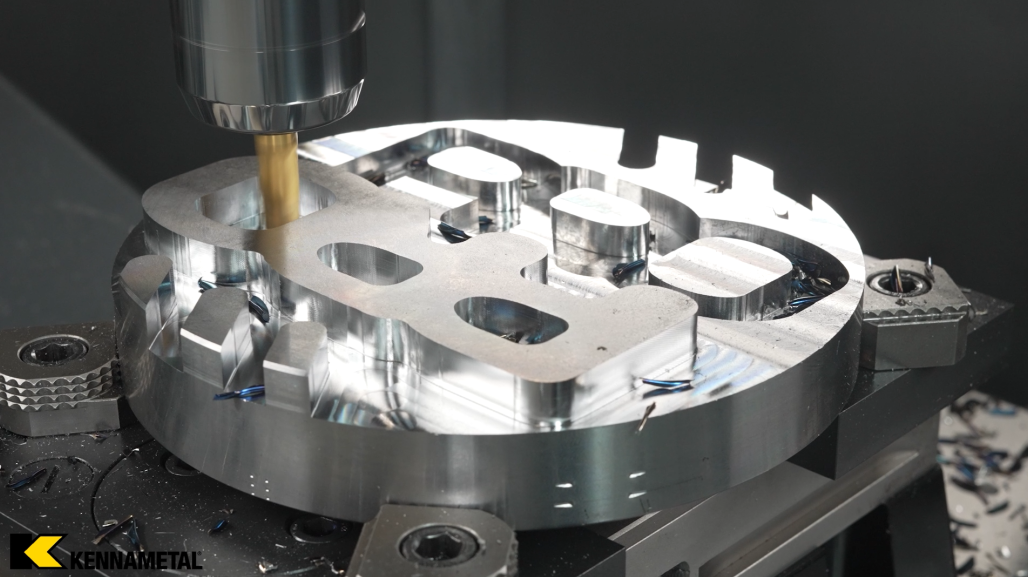

Join Jacob Sanchez in this episode of MSC Industrial Supply's "How To" series as he explores how Walter America builds strategic partnerships beyond traditional supplier relationships. Touring Walter’s state-of-the-art South Carolina campus, Jacob meets with experts who demonstrate how the company provides hands-on training, customized tooling solutions, and real-time production support. From Brian Schultz’s insights into technical training to Brian Baker’s demonstration of their unique troubleshooting approach, Walter America’s team highlights what sets them apart in the manufacturing industry. With facilities dedicated to tool reconditioning, ITAR-compliant defense production, and proprietary tool customization, Walter America shows how they empower customers to optimize performance without interrupting production. For anyone in the metalworking field, this tour offers a look into how Walter is redefining what it means to be a true partner in manufacturing.

For even more insights and expertise, check out MSC's Better MRO knowledge hub.

“How To” is a video content series from MSC Industrial Supply developed with the purpose of serving as a resource for all those who work in, support, and have a passion for the metalworking sector of the manufacturing industry.

Through How To, you’ll gain hands-on, practical advice from industry experts currently working in the field. At MSC, we are dedicated to providing real-world practical advice to improve your day-to-day operations.

For more How To videos, check out our MSC How To playlist and subscribe to our YouTube channel. And check out our other show, Tooling Up, on the MSC Tooling Up playlist.

Walter is a global leader in precision metalworking solutions, delivering high-performance tools for milling, turning, drilling, and threading. Serving aerospace, automotive, energy, and general engineering industries, we combine innovation with expertise to maximize productivity. More than a tool provider, Walter is a trusted partner, offering cutting-edge machining solutions that drive efficiency, quality, and performance in manufacturing worldwide.