What You Need to Know

In June 2015, ANSI published new guidelines for workplace first-aid kits.

Learn what is essential to have in your first-aid kit.

For more information, please contact your safety director or an MSC Industrial Supply sales associate.

Tips for making sure your workplace first-aid kit is up to code.

Since 2008, first-aid kits have grown in every aspect. “They’re larger, more diverse and have things they didn’t have before,” says Jeff Cohen, product manager at MSC Industrial Supply. “Kits today can handle a wider variety of problems.” Cohen reminds managers that workplaces are unique and that every kit should be stocked according to their individual needs as long as the kits meet the standards of the American National Standards Institute (ANSI).

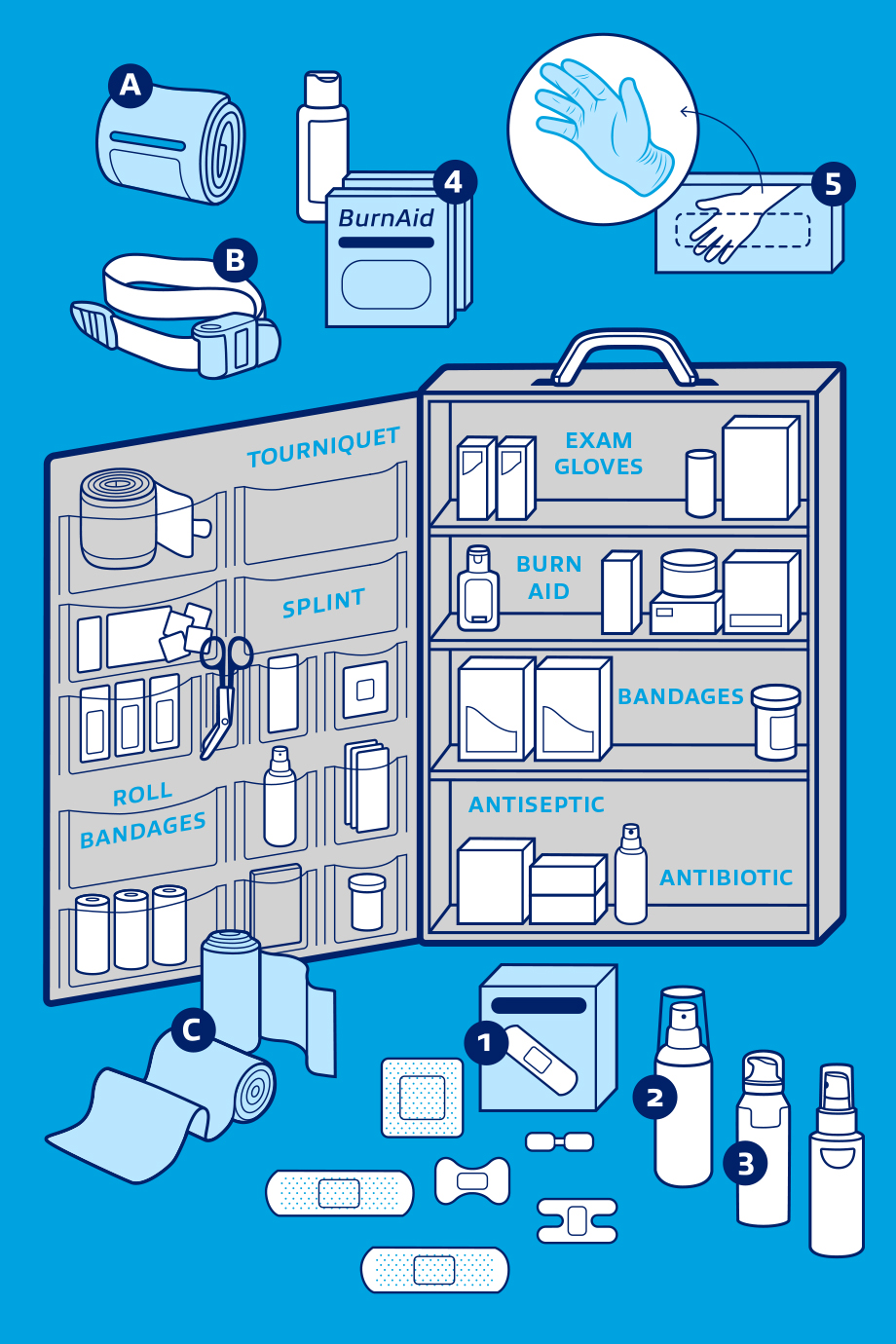

Whether it’s a restaurant or a welding shop, here are some expert tips to better prepare your workplace’s first-aid kit. The list includes a few new items (e.g., roller bandages and splints) and a few staples (e.g., adhesive bandages).

ALWAYS

Five first-aid essentials for every job site.

Adhesive Bandages

The most-used item when it comes worksite injuries. Every first-aid kit should have more adhesive bandages than anything else.

Antibiotic Application

A top-used item, applicable to everything from paper cuts to burn treatment.

Antiseptic

A must for anyone treating an injury. This helps reduce the risk of infection.

Burn Treatment

New “burn packs” have supplies to treat large and small burns. If you work in a place where burns are possible, consider a full kit devoted to burns.

Medical Exam Gloves

The best guard against infection and bacteria. They should be worn by anyone treating any skin injury.

SPECIALTY

Because manufacturing job sites have higher rates of injury, first-aid kits must be modified. These three items help treat serious injury.

Splint

For setting broken bones before the professionals arrive.

Tourniquet

To slow or stop bleeding from a laceration, a danger when working with heavy machinery.

2- and 4-Inch Roller Bandages

For dressing deeper or larger skin injuries.

TIPS

Remember these tactics to keep your first-aid kit in top order.

Security Check

Don’t store medications of any kind in a kit that’s open and accessible to everyone in the workplace.

Temperature Control

Don’t store the kit near moisture or extreme heat or cold.

Frequent Inspections

Check it regularly to make sure it’s orderly and nothing’s missing.

Workplaces have never been safer. According to the Department of Labor, fewer people have been hurt on the job every year, with the exception of 2012, for the past decade. Preparation is part of prevention, and an essential tool in job safety.

For a complete overview of the ANSI first-aid kit guidelines and details on quantities of each of these items for Class A and Class B kits, contact your MSC supplier.

Is your first-aid kit up to code?

Related Articles

TOOLING UP: Ansell: HyFlex Precision Comfort Gloves with Aerofit Technology

VIDEO: Case Study: Real Results and Impact: The MSC and Catamount Partnership Story

4x Output. One Simple Switch. Osborn Customer Stories

Mastering the Art of Waste Walks: From Preparations to Direct Observations