In business for over 80 years AccuformNMC is the leading manufacturer of American made safety communication products—including over 16,000 safety signs, tags, and labels. Our commitment is to support every safety ID need, with the best product, service and custom solutions in the industry. We offer the toughest signs and labels in the market, and guarantee them for life. Protected with Sign Muscle®, a clear liquid over-laminate strong enough to protect against fading under direct sunlight, it allows easy graffiti removal, resists chemical corrosion and is applied for free.

Lean manufacturing techniques help companies become more efficient and less wasteful. Here’s how National Marker Company (NMC) helps manufacturers develop smart strategies for workplace efficiency.

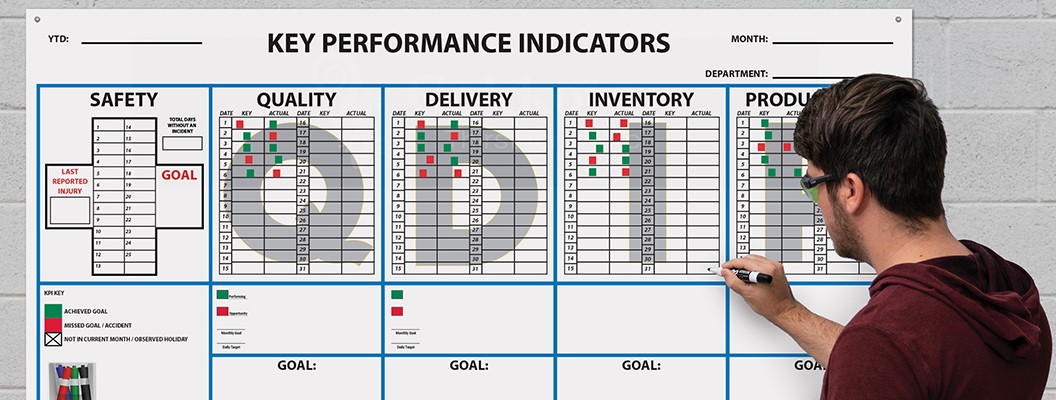

In recent years, manufacturers have started to implement lean manufacturing processes to minimize waste, which in turn reduces costs and boosts productivity.

What Is Lean Manufacturing?

The general idea of lean manufacturing is to identify (and eliminate) any action or process that needlessly adds to a company’s costs and that doesn’t add value.

Examples of this waste may include time spent searching for a misplaced tool shared between workstations, or the problem of overlooked inventory that builds up on the shop floor, taking up valuable space and impeding workers as they move about a facility.

.png?itok=k2IwFSM2)

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *