Forget the proverb that tough times don’t last: For the floors of some manufacturing facilities, distribution centers and warehouses, they often do.

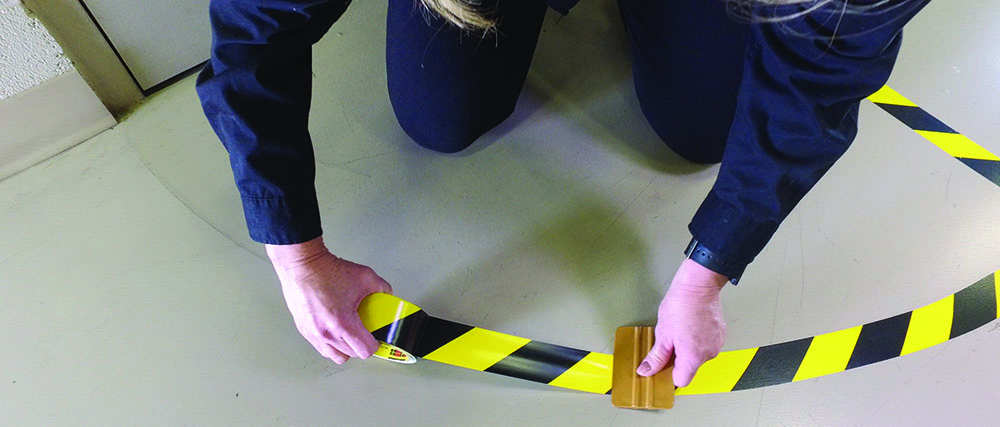

Which means that industrial marking tape used to identify work zones and hazard points needs to be tough, too—tough enough to handle the wear and tear of foot traffic, forklifts and workers dragging pallets.

“Imagine you’re trying to prepare a floor and put tape down in a facility with a floor area the size of four or five big-box retailers,” says Michael Engh, a business development manager at 3M. “You want to do that as infrequently as possible.”

That’s one of the goals that 3M’s Durable Floor Marking Tape 971 was designed to achieve. With a thickness of 19 mils (thousandths of an inch) and 2-, 3- and 4-inch widths, the 971 tape can be applied quickly and easily and removed cleanly from many surfaces, without leaving adhesive residue.

Less Time Scrubbing and Scraping

That’s a big benefit to the operators and maintenance workers who handle tape application and removal, Engh says, “because they don’t have to spend time on their knees, scrubbing and scraping old tape and adhesive.”

Removing old marking tape, whether it’s to replace faded markings or because of equipment relocation, can be both arduous and time-consuming, particularly if portions of tape cling stubbornly to floors and other surfaces. The more often the tape needs to be replaced, the more time must be devoted to the task—and taken away from other responsibilities.

That’s an increasing challenge in manufacturing facilities and machine shops, where a shortage of workers may reach 2.1 million by 2030, and managers are grappling with inflation, disrupted supply chains and the potential for higher raw-materials costs.

Because the colors in the 971 line permeate the entire thickness of the tape, they’re not dulled by wear and tear, Engh explains. That’s also a feature of the 471 line, which was previously 3M’s flagship floor-marking tape. Designed to resist both abrasion and solvents, the 471 features a slight elasticity that helps it conform tightly to uneven surfaces without lifting and retracting, the company says.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *