It takes a lot to get it right. To be a company that lasts more than 100 years by continually evolving and growing to meet the needs of our markets and customers. Our first-to-the-market and best-in-the-market approach led us to receive hundreds of patents over the years and truly shape an industry. We do what others don't in ways they can't. We offer innovative products backed by years of research and development. Beyond our quality products and reliable solutions, we add value for our customers through strong partnerships and a commitment to solving important problems. Brady offers solutions to help increase safety, security, productivity and performance throughout your facility—everything from printing systems, software and high-performance labels to facility signs, safety devices, expert safety services and more.

Improve equipment performance and reliability

Many companies engage in reactive maintenance, which is when you wait for a problem to show up and then fix it. But this method can be very expensive due to unplanned downtime. Innovators are now saving millions by switching to a Total Productive Maintenance system to ensure machines run optimally, while using predictive analytics and maintenance techniques to anticipate problems before they occur.

What is Total Productive Maintenance?

Total Productive Maintenance (TPM) is a system designed to stabilize equipment performance and reliability. The primary goals of TPM are to eliminate waste caused by accidents, emergency and unscheduled downtime, defects and speed losses.

TPM achieves this through proactive maintenance and improvement of the integrity of production, safety and quality systems to ensure all equipment is in top working condition, minimizing breakdowns and delays in manufacturing processes.

TPM is successful because it promotes group activities among shop floor team members. The knowledge base received from team members is used to improve equipment reliability and productivity, thereby lowering maintenance and operating costs.

This is achieved by:

- Adopting a lifecycle approach to improve the overall performance of production equipment

- Improving productivity by highly motivated workers, achieved through job enlargement

- Using voluntary small group activities to identify the cause of failure, as well as possible plant and equipment modification

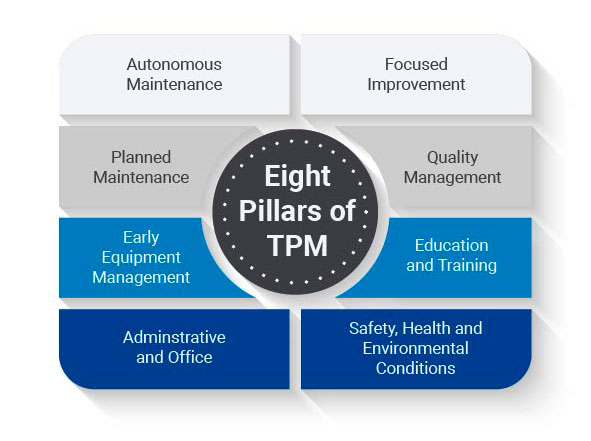

The Eight Pillars of TPM

- Autonomous maintenance

Routine maintenance, such as cleaning, lubrication and inspection, is performed by the machine operator.

- Focused improvement

Creating a voluntary small group to identify the cause of failure, as well as possible plant and equipment modification.

- Planned maintenance

Data-driven maintenance schedule using prediction and failure rates.

- Quality management

Creating production processes to detect and prevent errors.

- Early equipment management

Designing new equipment based on knowledge and understanding gained through TPM program.

- Education and training

Train and educate operators, maintenance and managers on necessary information to achieve TPM goals.

- Administrative and office

Seek ways to apply TPM to administrative and office functions.

- Safety, health and environmental conditions

Ongoing maintenance of a safe and healthy workplace.

Total Productive Maintenance Types

TPM combines three different types of maintenance, including autonomous maintenance, preventive maintenance, and early equipment maintenance. Each plays an essential role in a TPM program:

- Autonomous maintenance

Determines what maintenance tasks, adjustments or cleaning can be completed by operators due to their daily use of the equipment and knowledge of when a machine acts differently.

- Preventive Maintenance

Seeks ways to prevent the need for maintenance and introduce methods to monitor the critical areas that require attention in real-time.

- Early equipment maintenance

Strives to ensure all possible components are no/low maintenance through the design, specification or build of your equipment.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *