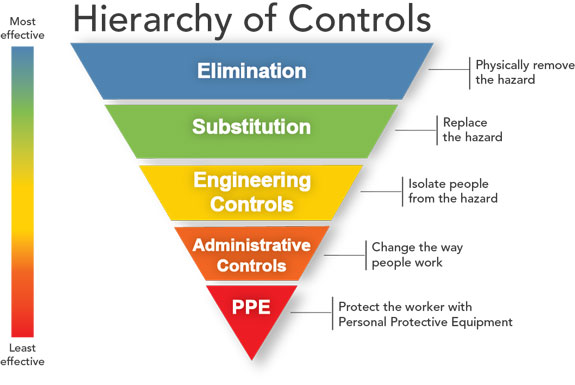

The inverted pyramid has five levels, ranging from most effective and wide sweeping to least effective and narrowest.

Here’s a quick breakdown of the levels:

Level 1: Elimination

Doing away with a risk is ideal, but NIOSH notes that it’s tricky to affect sweeping change in an existing process. But eliminating potentially deadly hazards must be addressed if those exist, OSHA says.

Some things are easier to fix than others but can still eliminate a hazard altogether. For instance, you could remove tripping hazards such as extension cords running across open areas of the shop floor.

Level 2: Substitution

At this level, a business might be able to substitute in a better control or make a temporary change until a final solution is implemented. Again, this can be difficult in long-ingrained processes or older environments. On an older machine, as an example, a kit can be used to add machines guards.

[Caveat: If a business is a startup or it’s redesigning operations, always go for eliminating hazards, suggests Jonathan Bach, coordinator of NIOSH’s Prevention through Design Initiative. “There’s all kinds of ways that we can design out hazards, and it’s being done more and more,” he says in Safety+Health.]

Level 3: Engineering Controls

These tactics are designed “to remove the hazard at the source, before it comes in contact with the worker,” NIOSH says.

“The initial cost of engineering controls can be higher than the cost of administrative controls or PPE, but over the longer term, operating costs are frequently lower, and in some instances, can provide a cost savings in other areas of the process.”

During initial shop floor design, plans could include the creation of soundproof rooms and stations for loud machines, eliminating the potential hearing harm to nearby workers.

Level 4: Administrative Controls

When an environment is well established, creating policies for very specific hazards will work, but it’s not ideal because it doesn’t eliminate the risk.

The use of signage to indicate possible hazards near open pit areas as well has providing training and policies about the appropriate use of fall PPE when working in these areas are types of administrative controls that a business might implement.

Compare PPE alternatives using our Safety Products Selector.

Level 5: Personal Protective Equipment

The last recourse to address a risk is PPE, such as ensuring workers at machines have the appropriate cut-resistant gloves and eyewear.

It’s absolutely necessary to protect workers from exposure to hazards that could harm or kill them, but NIOSH notes that there’s generally more chance for error and for an incident to occur when the control is PPE.

As part of a separate effort, called Total Worker Health, NIOSH has created an accompanying version of its Hierarchy of Controls that it says “emphasizes organizational-level interventions to protect workers’ safety, health and well-being.”

These focus more on behaviors and practices, with the aim of helping eliminate the hazards versus mediate to reduce the risk of exposure to workers.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *